WELCOME TO OUR BLOG

Cotton Mop Quality Control Testing Solution

Cotton mops are indispensable cleaning tools widely used in both commercial and residential environments. Ensuring that these mops meet the required quality standards is crucial to ensuring their effectiveness and longevity. Proper cotton mop quality control testing ensures that mops perform well and maintain their integrity throughout their lifecycle.

We’ll explore the significance of cotton mop quality control testing, focusing on the critical tests that define the durability and performance of cotton mops.

Why Cotton Mop Quality Control Is Essential

When it comes to cleaning, the performance of a cotton mop can make a huge difference in terms of efficiency and durability. Whether used in industrial settings, hospitals, or homes, the mop’s ability to withstand wear and tear, absorb liquids, and resist breakage is paramount. Poor-quality mops can lead to inefficiencies, increased maintenance costs, and dissatisfaction among users. Therefore, cotton mop quality control testing plays a pivotal role in manufacturing high-performance mops.

The key aspects of cotton mop quality control testing include:

- Tensile strength: This determines how much force a cotton mop can endure before it tears or breaks.

- Elasticity: This test measures how well the cotton mop returns to its original shape after being stretched.

- Durability: This assesses how well the mop holds up after repeated use and washing.

Cotton Mop Quality Control Testing Solution

1. Cotton Mop Tensile Strength Testing

Tensile strength testing is crucial for ensuring that cotton mops can withstand the physical strain they endure during cleaning tasks. The test measures the force required to pull the cotton fibers apart until they break. This is vital because mops are subjected to significant physical stress while being used to scrub floors or absorb liquids. A cotton mop with low tensile strength will break down quickly, resulting in poor performance and the need for more frequent replacements.

To perform the tensile strength test, manufacturers use specialized equipment to apply a pulling force on the cotton strands, measuring the amount of force needed to break the material. The strength of the threads is then evaluated to ensure they meet the required standards for industrial use.

2. Cotton Mop Elasticity Testing

Elasticity refers to the ability of a cotton mop to return to its original shape after being stretched or compressed. This characteristic is particularly important because mops are frequently wrung out and pulled during use, and they must recover to their original form to maintain effectiveness.

Elasticity testing involves stretching the mop’s fibers and then releasing the tension to observe how well the mop returns to its original state. Mops with poor elasticity may not return to their initial shape and could become misshapen over time, reducing their cleaning performance.

3. Cotton Mop Durability Testing

Durability testing is designed to simulate the conditions a cotton mop will face over its lifetime. This includes testing its performance after repeated washing, exposure to various cleaning chemicals, and prolonged use. The test evaluates whether the mop fibers remain intact and retain their cleaning efficiency even after being subjected to harsh conditions.

Manufacturers typically conduct these tests by subjecting the mop to cycles of washing, drying, and usage, monitoring its ability to withstand this prolonged exposure to stress. A durable mop will retain its cleaning ability and structure, even after hundreds of uses.

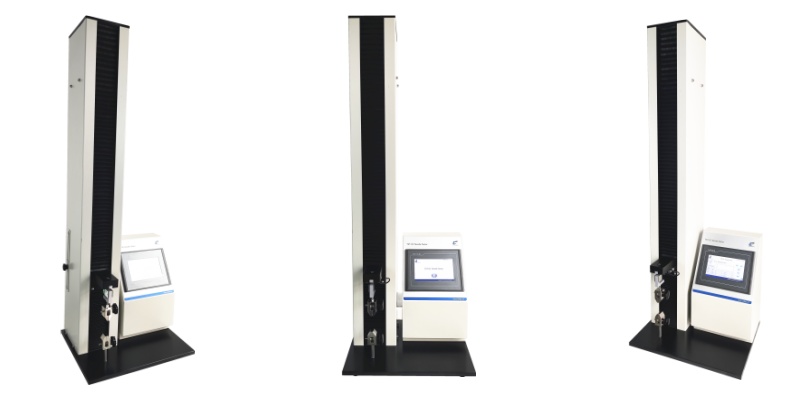

Recommended Product for Cotton Mop Quality Control Testing

At Cell Instruments, we offer advanced testing equipment designed to accurately assess the tensile strength, elasticity, and durability of cotton mops. Our Cotton Mop Quality Control Testers are equipped with precision sensors to measure these critical properties. The equipment provides fast, reliable results that allow manufacturers to ensure their products meet the highest industry standards. With customizable testing options, you can tailor the tests to suit your specific production needs.

TST-01 Tensile Tester

Learn about cotton mop quality control testing, including tensile strength, elasticity, and durability tests. Improve the consistency and performance of your cotton mops.

Cell Instruments

Manufactuer and Factory

Join us get the best lab testing solution for mop quality

FAQs about Cotton Mop Quality Control Testing

Tensile strength testing measures the force required to break the cotton fibers of a mop, ensuring that the mop can withstand physical stress during cleaning tasks.

Elasticity testing determines how well a cotton mop returns to its original shape after being stretched or compressed, which is crucial for maintaining its cleaning performance over time.

Durability testing simulates the long-term use of cotton mops by subjecting them to repeated washing, drying, and chemical exposure to ensure they maintain their effectiveness and structure.

Using advanced testing equipment to assess tensile strength, elasticity, and durability is the best way to ensure consistent quality control. Customizable testing solutions can help meet specific quality requirements.