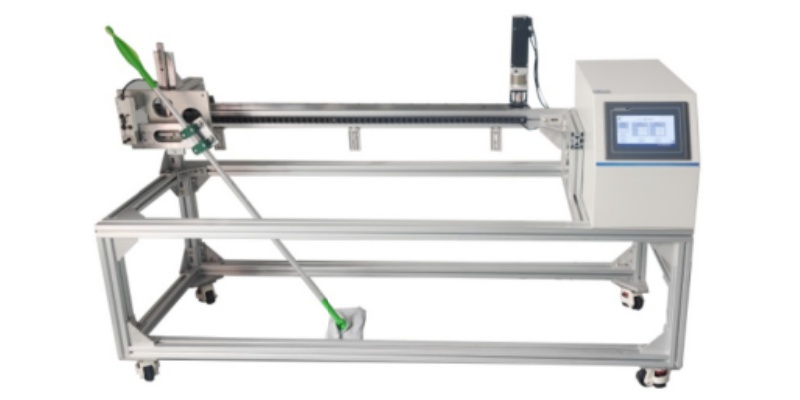

Moppikankaan kitkakertoimen testaaja

Paras testaaja mopin laadun testaamiseen

– Mopin COF-testi

Siivousvälineiden, kuten moppien, suorituskyky on kriittinen niiden tehokkuuden kannalta jokapäiväisessä käytössä. Olipa kyseessä keittiön lattioiden, ikkunoiden tai teollisuuspintojen puhdistus, mopin laatu voi vaikuttaa merkittävästi puhdistustehokkuuteen. Yksi tärkeimmistä mopin suorituskyvyn määrittävistä tekijöistä on Kitkakerroin (COF). The Moppikankaan kitkakertoimen testaaja on suunniteltu mittaamaan tätä tärkeää ominaisuutta varmistaen, että mopit säilyttävät optimaalisen tasapainon kitkan ja käytettävyyden välillä.

Johdatus moppikankaan kitkakertoimen testaamiseen

COF-testi mittaa vastustusta, jonka mopin kangas kokee liikkuessaan pinnan poikki. Liiallinen kitka voi tehdä puhdistustehtävästä työvoimavaltaisemman, kun taas riittämätön kitka voi johtaa huonoihin puhdistustuloksiin. Oikealla tasapainolla mopit voivat toimia tehokkaasti ja mukavasti. Valmistajille ja laadunvalvontalaboratorioille, joilla on luotettava mopin COF-testi järjestelmä on olennainen korkealaatuisten tuotteiden kehittämiseksi ja ylläpitämiseksi.

The Moppikankaan kitkakertoimen testaaja käytetään ensisijaisesti puhdistusmateriaalien kitkaominaisuuksien arvioimiseen, kuten mikrokuitumappityynyjen, vaahtomoppien (joko selluloosaa, kumia tai muovia) ja muiden vastaavien materiaalien sienimoppien. Näiden materiaalien ominaisuudet vaihtelevat suuresti, joten on tärkeää mitata niiden kitkakäyttäytymistä erilaisissa olosuhteissa.

Mop COF -testin sovellukset

The mopin COF-testi auttaa valmistajia määrittämään, kuinka moppi toimii tosielämän puhdistusskenaarioissa. Esimerkiksi mopit, joilla on suuri kitka, voivat vaatia enemmän työntää, mikä lisää työvoiman intensiteettiä. Toisaalta vähäkitkaiset mopit eivät välttämättä tartu pintoihin tehokkaasti, mikä johtaa huonoihin puhdistustuloksiin. Näiden kahden ääripään tasapainottaminen on välttämätöntä mopin käytettävyyden ja puhdistustehon varmistamiseksi.

Tuotekehityksen lisäksi tämä testi on korvaamaton myös laadunvarmistuksen kannalta. Moppien valmistajat ja toimittajat voivat käyttää mopin laadun testauskone varmistaa, että jokainen tuote-erä täyttää alan puhdistustehokkuutta, kestävyyttä ja turvallisuutta koskevat standardit.

Mop COF -testauksen testausmenetelmät

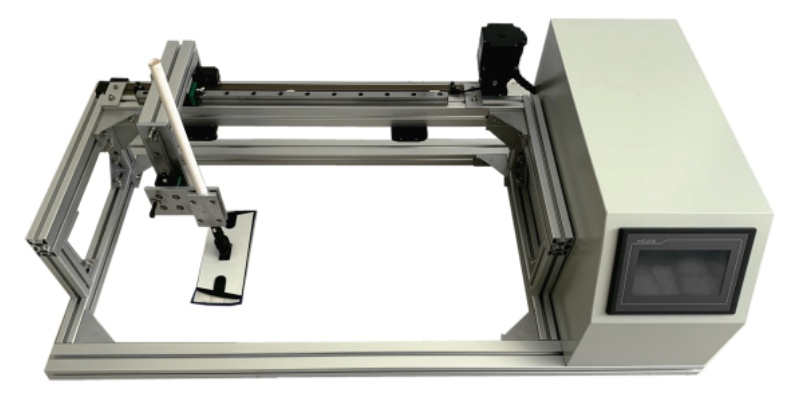

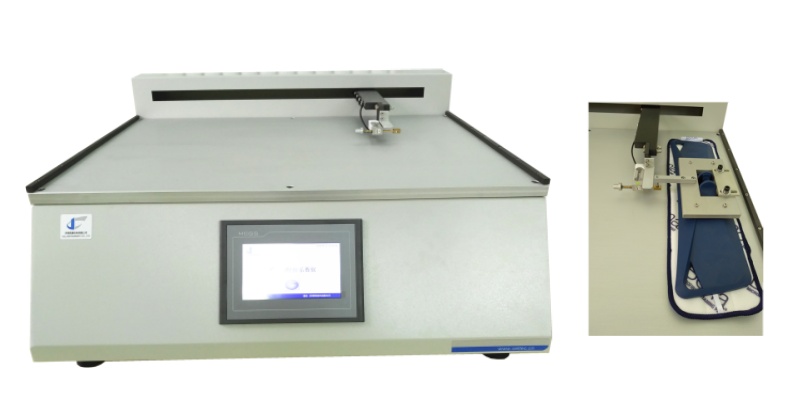

Suoritusprosessi a Moppikankaan kitkakertoimen testi sisältää useita yksinkertaisia mutta kriittisiä vaiheita. Tässä on yksityiskohtainen katsaus menettelyyn:

-

1. Näytteen valmistus:

Moppiliina kiinnitetään huolellisesti alumiini- tai muovikehykseen. Kehys auttaa kiinnittämään kankaan paikalleen testauksen aikana ja varmistaa, että näyte jakautuu tasaisesti. -

2. Testaa asetukset:

Kun näyte on kiinnitetty, koko koottu osa (joka sisältää moppiliinan ja sen kehyksen) asetetaan tietylle kuormitukselle. Käytetty paino on tyypillisesti standardoitu simuloimaan todellisia olosuhteita, mikä varmistaa, että testitulokset ovat tarkkoja ja luotettavia. -

3. Mittaus:

Reki, joka on varustettu tasaisella pinnalla (tyypillisesti kooltaan 100 x 100 mm ja painaa 225 g ± 1 g), vedetään sitten moppikankaan yli vakionopeudella 500 mm/min 500 mm matkan. Tämän prosessin aikana mitataan kelkan liikuttamiseen tarvittava voima. Tätä voimaa verrataan painon kohdistamaan kohtisuoraan voimaan kitkakertoimen laskemiseksi.

Staattinen COF (µs)

Tämä mittaa voimaa, joka tarvitaan liikkeen käynnistämiseen. Se kuvastaa kitkavastusta, joka on voitettava puhdistusprosessin aloittamiseksi.

Kineettinen COF (µd)

Tämä mittaa voimaa, joka tarvitaan liikkeen ylläpitämiseen kelkan ollessa liikkeessä. Se auttaa arvioimaan jatkuvan puhdistuksen aikana kokevia kitkavoimia.

Näiden mittausten tulokset tallennetaan ja niitä käytetään moppiliinan kitkaominaisuuksien arvioimiseen. Vertaamalla staattisia ja kineettisiä COF-arvoja valmistajat voivat paremmin ymmärtää, kuinka moppi toimii todellisissa olosuhteissa.

Tekniset tiedot

The Moppikankaan kitkakertoimen testaaja on suunniteltu suurta tarkkuutta ja monipuolisuutta ajatellen. Alla on laitteen tärkeimmät tekniset tiedot:

| Parametri | Erittely |

| Voiman kantama | 100 N |

| Resoluutio | 0.5% FS |

| Nopeusalue | 1-1000 mm/min |

| Nopeuden tarkkuus | 0,1 mm/min |

| Kelkan koko | 100 x 100 mm |

| Kelkan paino | 225 g ± 1 g |

| Näytteen paino | 520 g ± 1 g |

| Aivohalvaus | 500 mm |

| Kuormituskennon korkeus | 50 mm |

| Testitila | 5 ryhmää |

| Virtalähde | 110-220 V |

Nämä tekniset tiedot mahdollistavat Moppikankaan kitkakertoimen testaaja vastaamaan valmistajien ja testauslaboratorioiden erilaisiin tarpeisiin tarjoamalla tarkkoja ja tarkkoja mittauksia joka kerta.

Mopin laaduntestauskoneen tärkeimmät ominaisuudet

The Moppikankaan kitkakertoimen testaaja tarjoaa useita edistyneitä ominaisuuksia, jotka on suunniteltu tarjoamaan tarkat ja luotettavat testaukset valmistajille ja laadunvalvontaryhmille. Tässä on joitain tärkeimpiä ominaisuuksia, jotka erottavat tämän koneen muista:

Järjestelmä käyttää PLC:tä (Programmable Logic Controller) varmistaakseen korkean tarkkuuden testiparametrien ohjauksessa. HMI (Human-Machine Interface) -näyttö tarjoaa käyttäjille intuitiivisen käyttöliittymän asetusten tarkkailua ja säätämistä varten.

Testausnopeus on säädettävissä välillä 1 mm/min – 1000 mm/min, jolloin käyttäjät voivat simuloida erilaisia todellisia skenaarioita. Lisäksi testeri tarjoaa valikoiman muokattavia testiparametreja, jotka sopivat erilaisiin moppimateriaaleihin ja -vaatimuksiin.

Pitkäkestoiseen käyttöön suunniteltu testeri tarjoaa luotettavat tulokset vaativissakin olosuhteissa. Se on ihanteellinen sekä tutkimukseen ja kehitykseen että laadunvarmistusprosesseihin.

Yksinkertaisen ja helposti ymmärrettävän käyttöliittymän ansiosta jopa rajoitetun teknisen kokemuksen omaavat voivat käyttää sitä mopin laadun testauskone tehokkaasti.

Usein kysytyt kysymykset puhdistustehokkuudesta

1. Mihin moppikankaan kitkakertoimen testaajaa käytetään?

Testeriä käytetään moppiliinojen kitkakertoimen mittaamiseen varmistaen, että mopit tarjoavat optimaalisen puhdistustehon ilman liiallista työvoimaa.

2. Mitä eroa on mop cof -testin staattisen ja kineettisen COF:n välillä?

Staattinen COF mittaa voimaa, joka tarvitaan mopin liikkeen käynnistämiseen, kun taas kineettinen COF mittaa voimaa, joka tarvitaan jatkuvan liikkeen ylläpitämiseen puhdistuksen aikana.

3. Voidaanko moppikankaan kitkakertoimen testaajaa käyttää eri moppityypeille?

Kyllä, testeri soveltuu erilaisten moppimateriaalien, mukaan lukien mikrokuitu- ja sienimoppien, testaamiseen.

4. Mitä pintoja voidaan testata Mop COF -testauskoneella?

Testerillä voidaan simuloida erilaisia puhdistusolosuhteita, mukaan lukien märät, kuivat ja pölyiset pinnat.

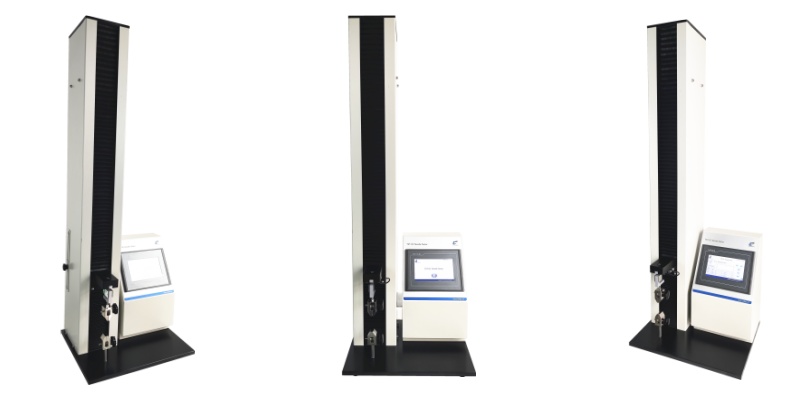

Aiheeseen liittyvä mopin laadunvalvontaratkaisu

Etsitkö luotettavaa Mop COF -testeriä?

Älä missaa mahdollisuutta optimoida laadunvalvontaprosessejasi uusimpien laitteiden avulla.