Mop tartóssági vizsgálata

Mop ellenőrzés minőségi ellenőrzés

-Mop használat szimuláció

A felmosók tartósságának vizsgálata elengedhetetlen a gyártók és a minőségellenőrzési csapatok számára a különféle tisztítási környezetekben használt felmosók rugalmasságának és élettartamának felméréséhez. Ezzel a vizsgálati módszerrel biztosítható, hogy a felmosók kibírják az otthonokban, irodákban, szállodákban és ipari környezetben történő gyakori használat követelményeit.

A mop tartóssági vizsgálatának jelentősége

A felmosó tartósságának vizsgálata fontos annak meghatározásához, hogy egy felmosó hányszor tudja megőrizni tisztítóképességét. Ez biztosítja, hogy a mop megfeleljen a minőségi előírásoknak, és megőrizze használhatóságát a fogyasztók kezében. A tesztelés segít a gyártóknak azonosítani a felmosó konstrukciójának gyenge pontjait, például a felmosórongy anyagával, varrásával vagy általános kialakításával kapcsolatos problémákat, amelyek idő előtti kopáshoz és elhasználódáshoz vezethetnek.

A felmosó tartóssága közvetlenül befolyásolja a tisztítás hatékonyságát és a felhasználó elégedettségét. Ha egy felmosórongy túl gyorsan elhasználódik, az megnövekedett karbantartási költségeket, gyakoribb cseréket és a tisztítás hatékonyságának csökkenését eredményezheti.

Kulcstényezők a felmosók tartósságának vizsgálatában

A mop tartóssági vizsgálata számos tényezőt értékel, többek között:

Ezek a tényezők hozzájárulnak a felmosó általános teljesítményéhez és élettartamához. Ezen szempontok tesztelése biztosítja, hogy a felmosó megőrizze működőképességét, és ne hibásodik meg idő előtt.

Szövet szilárdsága

Mennyire bírja a felmosó anyag az ismételt súrolást és nyomást.

Kopás

A felmosó azon képessége, hogy ellenáll a kopásnak, aprításnak vagy a tisztítási hatékonyság elvesztésének.

Fogantyú és rögzítési szilárdság

Milyen jól bírja a felmosó fogantyúját és rögzítési mechanizmusait ismételt használat során.

Felmosóhasználati szimuláció – a valós körülmények utánzása

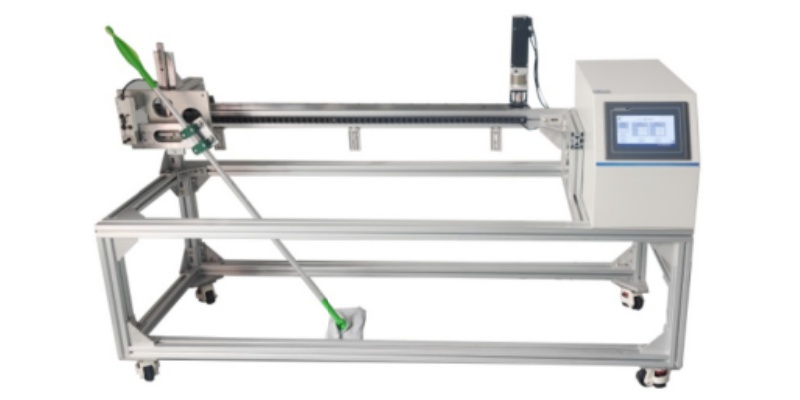

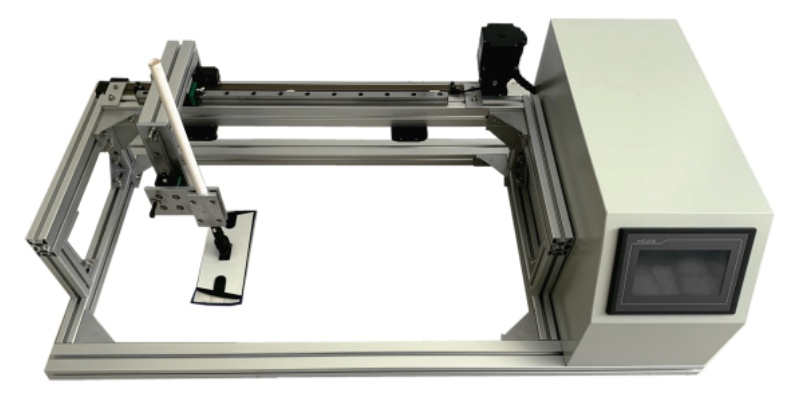

A felmosóhasználat-szimuláció a felmosó tartóssági vizsgálatának kulcsfontosságú eleme. Ez magában foglalja azoknak a feltételeknek a megismétlését, amelyekkel a mop a napi használat során találkozik, beleértve a tisztított felületek típusát, az alkalmazott nyomást és a tisztítási ciklusok számát.

Tesztelési eljárás a felmosóhasználat-szimulációhoz

- A minta előkészítése: A felmosó mintát úgy készítik elő, hogy azt egy kerethez vagy egy vizsgálóelemhez rögzítik. A felmosófejet jellemzően tesztelik, mivel ez az a terület, amely a leginkább kitett kopásnak.

- Mozgásszimuláció: A felmosórongy különféle mozgási mintáknak van kitéve. Ezek a minták tartalmazhatnak csúszó vagy súroló mozdulatokat, amelyek valódi tisztítási körülményeket szimulálnak olyan felületeken, mint a csempepadló, a fa és az üveg.

- Nyomás alkalmazása: A tesztkezelő beállítja a felmosótörlőre kifejtett nyomást, ami utánozza, hogy a felhasználó milyen erősen nyomja meg a tisztítás során.

- Ciklusteszt: A felmosót meghatározott számú tisztítási ciklusnak vetik alá, és minden ciklus egy teljes tisztítási löketet jelent.

- Teszt utáni ellenőrzés: A tesztciklusok befejezése után a felmosórongyot részletesen megvizsgálják, hogy értékeljék az anyag, a fogantyú és a rögzítési mechanizmus kopását.

A valós tisztítási körülmények pontos szimulálásával ez a tesztelési módszer biztosítja, hogy a mop továbbra is hatékonyan működjön a mindennapi használat során. Segít azonosítani azokat a potenciális hibákat a felmosó kialakításában vagy az anyagválasztásban, amelyek idő előtti meghibásodást okozhatnak.

Felmosó szemle: A kopás és a teljesítmény értékelése

A felmosófelmosó ellenőrzése a felmosóroncs tartóssági vizsgálati folyamatának döntő része. Miután a felmosó több tisztítási cikluson átesett a felmosóhasználat szimulációjában, ellenőrzést végeznek a különböző teljesítménymutatók értékelése céljából. Ez az ellenőrzés általában a következőkre összpontosít:

A szövet integritása

Megvizsgálja, hogy a felmosó szálai épek-e, vagy elkoptak-e vagy elszakadtak-e valamelyik szál.

Fogantyú Tartósság

Ellenőrizze, hogy a felmosó fogantyúján nincs-e repedés, meghajlás vagy meglazulás.

Rögzítési mechanizmus

Biztosítja, hogy a felmosófej biztonságosan rögzítve maradjon a fogantyúhoz, csúszás vagy leválás nélkül.

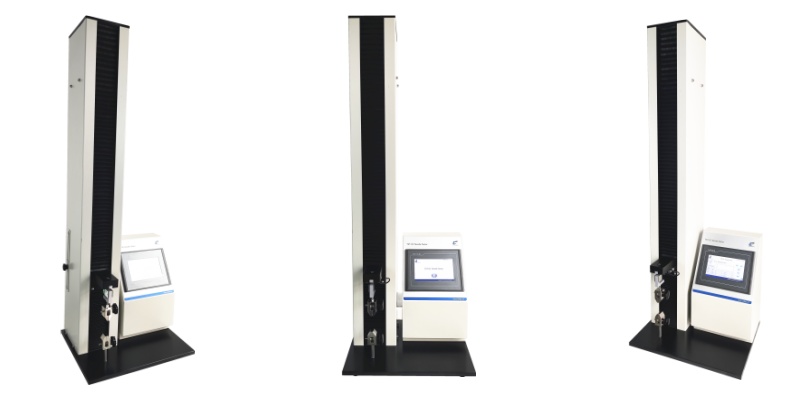

A felmosó ellenőrzés célja annak igazolása, hogy a felmosó még hosszabb használat után is működőképes és megbízható marad. Segít megállapítani, hogy a felmosó kibírja-e a tipikus tisztítási tevékenységek során fellépő igénybevételeket, így biztosítva, hogy a termék megfeleljen a fogyasztók tartóssági igényeinek. Az ellenőrzés történhet szemrevételezéssel vagy szakítógép segítségével. A szemrevételezés magában foglalja a felmosórongy gondos vizsgálatát fizikai sérülés, kopás vagy hibás működés jelei szempontjából. Ezzel szemben a húzógépek szabályozott erővel tesztelhetik az anyagok szilárdságát, például a felmosó fogantyúját vagy a rögzítési pontokat, hogy biztosítsák, hogy nyomás alatt ne tönkremenjenek. A vizuális és mechanikai ellenőrzés ezen kombinációja átfogó értékelést nyújt a felmosó teljes tartósságáról és teljesítményéről valós körülmények között.

GYIK a Mop COF teszteléséről

A felmosó tartóssági vizsgálata biztosítja, hogy a felmosó kibírja az ismételt használatot anélkül, hogy elveszítené hatékonyságát, így hosszú élettartamot biztosít a fogyasztóknak.

A felmosófelmosó vizsgálat során keresik a kopás jeleit, például az anyag kopását, repedéseket a nyélben vagy a felmosófej leválását a nyélről.

A tartóssági vizsgálat azonosítja a felmosó anyagának vagy szerkezetének gyengeségeit. Például a felmosórongy kopásállósága és a felmosó fogantyújának csatlakozási szilárdsága, ami lehetővé teszi a gyártók számára, hogy fejlesztéseket hajtsanak végre a tervezésben az erő és a teljesítmény fokozása érdekében.

Kapcsolódó Mop minőségellenőrzési megoldás

Megbízható mop tartóssági vizsgálatot keres?

Ne hagyja ki a lehetőséget, hogy minőség-ellenőrzési folyamatait a legmodernebb berendezésekkel optimalizálja.