Mop COF vizsgálati módszer

A felmosórongy COF vizsgálata döntő fontosságú a felmosórongy minőségének elemzéséhez. A súrlódási együttható (COF) kiértékelésével a gyártók és a minőségbiztosítási csapatok meghatározhatják, hogy a felmosók milyen hatékonyan teljesítenek a különböző felületeken. Ez a tesztelés létfontosságú a tisztítási hatékonyság és a használhatóság közötti egyensúly biztosításához, különösen otthoni, irodai és ipari környezetben történő alkalmazások esetén.

Felmosórongy minőségi elemzése

- Mop súrlódási együttható vizsgálata

A Mop COF tesztelésének megértése

A felmosó COF tesztelése magában foglalja a felmosó felülete és a padló közötti súrlódási ellenállás mérését. A súrlódási együttható azt jelzi, hogy mekkora erő szükséges ahhoz, hogy a felmosót a felületen keresztül mozgassa, ami befolyásolja a tisztítási teljesítményt és a felhasználói élményt.

A COF jelentősége a mop tesztelésben

Optimális tisztítási hatékonyság

A lapos felmosóknak, más tisztítóeszközökhöz hasonlóan, optimális súrlódási együtthatóra (COF) van szükségük a szennyeződések, port és szennyeződések hatékony eltávolításához. A megfelelő COF-értékkel rendelkező felmosók simán siklanak a felületeken, miközben megtartják a kiváló tisztítóerőt. Például egy túl magas súrlódási tényezőjű lapos felmosó nehezen mozog, ami munkaigényessé teszi a tisztítást, míg az alacsony COF nem megfelelő tisztítási teljesítményt eredményezhet.

Könnyű használat

A lapos felmosók kiegyensúlyozott COF-ja kulcsfontosságú a felhasználói kényelem szempontjából. A lapos felmosókat gyakran nagy területeken használják, és elengedhetetlen a könnyű mozgás. A túl sok súrlódás nehézzé és fárasztóvá teszi a felmosást, míg a túl kicsi kihívást jelenthet a szennyeződés hatékony felszedésében. A COF tesztelésével a gyártók minimális erőfeszítéssel optimalizálhatják a felmosó kialakítását, biztosítva, hogy a felhasználók könnyedén és fáradság nélkül tisztíthassanak.

Tartósság

Lapos felmosóknál a tartósság kulcsfontosságú tényező. A COF teszt biztosítja, hogy a felmosó tartós használat után is egyenletes teljesítményt nyújtson. Az ideális COF-értékkel rendelkező felmosók idővel jól teljesítenek, még gyakori tisztítási ciklusok esetén is. A tesztelés segít meghatározni, hogy a felmosóanyag hosszú távon megőrzi-e tisztítási hatékonyságát és használhatóságát.

A Mop COF tesztelésének fő szempontjai

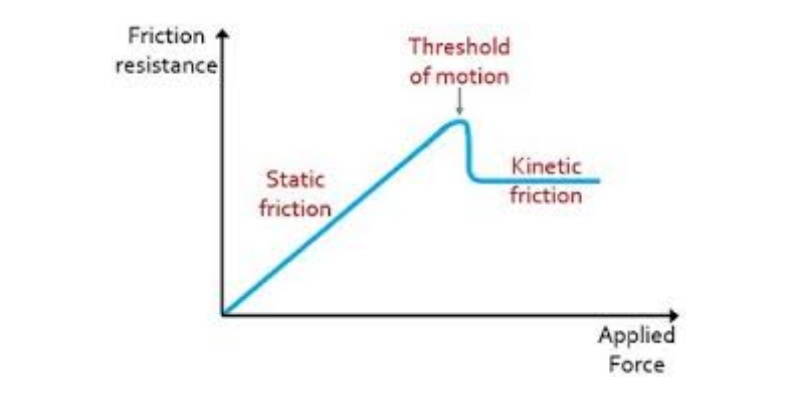

Statikus és kinetikus COF

- Statikus COF (µs): A mozgás elindításához szükséges erő.

- Kinetikus COF (µd): A mozgás fenntartásához szükséges erő.

Mindkettő kritikus fontosságú annak értékeléséhez, hogy a felmosó anyag hogyan lép kölcsönhatásba a különböző felületekkel különböző körülmények között, például nedves, száraz vagy poros környezetben.

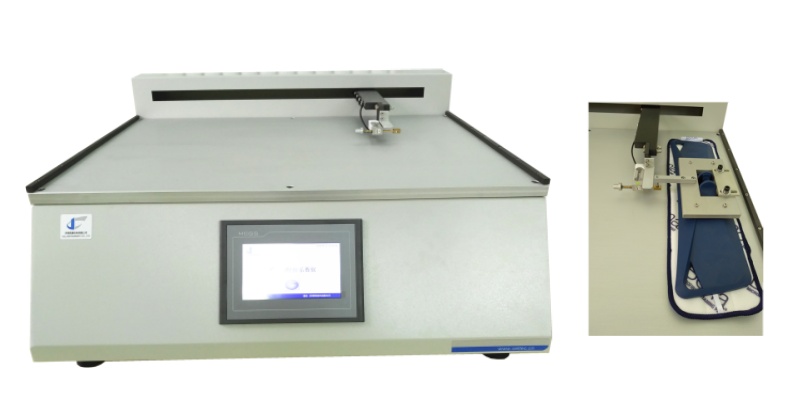

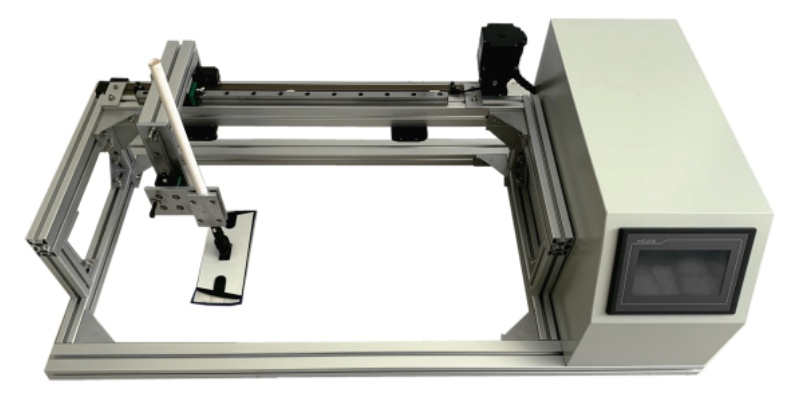

Vizsgálati módszertan

- Rögzítse a felmosó anyagot egy keretre.

- Helyezze a keretezett anyagot meghatározott súly alá.

- Húzza a szerelvényt szabványos sebességgel (pl. 500 mm/perc) meghatározott távolságra (pl. 500 mm).

- Jegyezze fel a statikus és kinetikus COF értékeket.

A Mop COF tesztelésének alkalmazásai

Felmosórongy minőségi elemzése

A COF értékelése segít azonosítani azokat az anyagokat, amelyek a legjobb egyensúlyt kínálják a súrlódás és a használhatóság között. Ez különösen fontos az otthonokban és az iparban használt mikroszálas felmosókra, szivacsos felmosókra és habblokkokra.

Mop súrlódási együttható vizsgálata

Ez a speciális értékelés biztosítja, hogy a felmosó képes kezelni a különféle tisztítási forgatókönyveket, mint például:

- Folyadékok hatékony felszívása.

- A makacs porszemcsék eltávolítása.

- Sima csúszás nedves vagy száraz felületeken, túlzott erőhatás nélkül.

A Mop COF tesztelésének előnyei

Fokozott teljesítmény

Biztosítja, hogy a felmosók optimális tisztítási eredményeket biztosítanak a különféle alkalmazásokban.

Fokozott tartósság

Segíti a gyártókat olyan termékek létrehozásában, amelyek idővel megőrzik a teljesítményt.

Felhasználói elégedettség

Csökkenti a fizikai megterhelést, megkönnyítve a tisztítási feladatokat a felhasználók számára.

GYIK a Mop COF teszteléséről

1. Mi a célja a felmosó súrlódási együttható vizsgálatának?

A felmosó súrlódási együttható vizsgálata értékeli a súrlódási együtthatót, hogy biztosítsa a felmosók hatékonyak, tartósak és könnyen használhatók a különböző felületeken.

2. Miért fontosak a statikus és kinetikus COF értékek?

A statikus COF azt határozza meg, hogy mekkora erőfeszítés szükséges a mozgás elindításához, míg a kinetikus COF azt az erőt jelzi, amely a mozgás fenntartásához szükséges a tisztítás során.

3. Hogyan javítja a COF-teszt a felmosófelszerelést?

Az optimális súrlódási szintek meghatározásával a gyártók olyan felmosókat tervezhetnek, amelyek egyensúlyban tartják a tisztítási hatékonyságot a felhasználói kényelemmel.

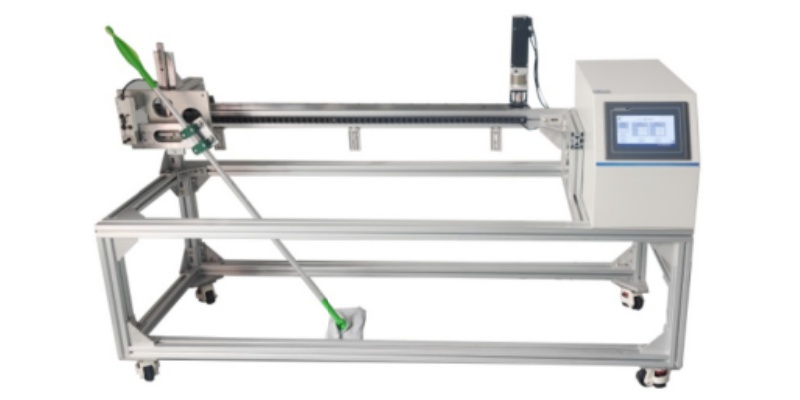

Kapcsolódó Mop minőségellenőrzési megoldás

Megbízható felmosórongy minőségelemzőt keres

Ne hagyja ki a lehetőséget, hogy minőség-ellenőrzési folyamatait a legmodernebb berendezésekkel optimalizálja.