Penguji Koefisien Gesekan Kain Pel

Penguji Terbaik untuk Pengujian Kualitas Pel

– Uji COF Pel

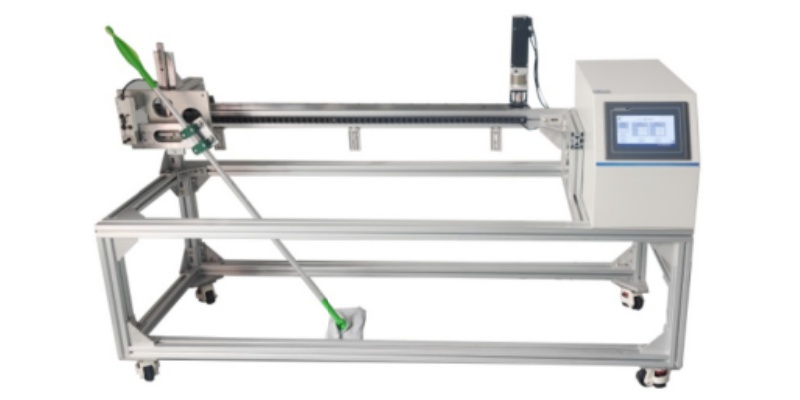

Kinerja alat pembersih seperti pel sangat penting untuk efektivitasnya dalam penggunaan sehari-hari. Baik itu membersihkan lantai dapur, jendela, atau permukaan industri, kualitas pel dapat memengaruhi efisiensi pembersihan secara signifikan. Salah satu faktor terpenting yang menentukan kinerja pel adalah Koefisien Gesekan (COF). Itu Penguji Koefisien Gesekan Kain Pel dirancang untuk mengukur properti penting ini, guna memastikan bahwa kain pel mempertahankan keseimbangan optimal antara gesekan dan kegunaan.

Pengantar Pengujian Koefisien Gesekan Kain Pel

Uji COF mengukur hambatan yang dialami kain pel saat bergerak di atas permukaan. Gesekan yang berlebihan dapat membuat tugas pembersihan menjadi lebih padat karya, sementara gesekan yang tidak memadai dapat menyebabkan hasil pembersihan yang buruk. Dengan keseimbangan yang tepat, kain pel dapat bekerja secara efisien dan nyaman. Bagi produsen dan laboratorium kontrol kualitas, memiliki kain pel yang andal uji COF pel sistem sangat penting untuk mengembangkan dan memelihara produk berkualitas tinggi.

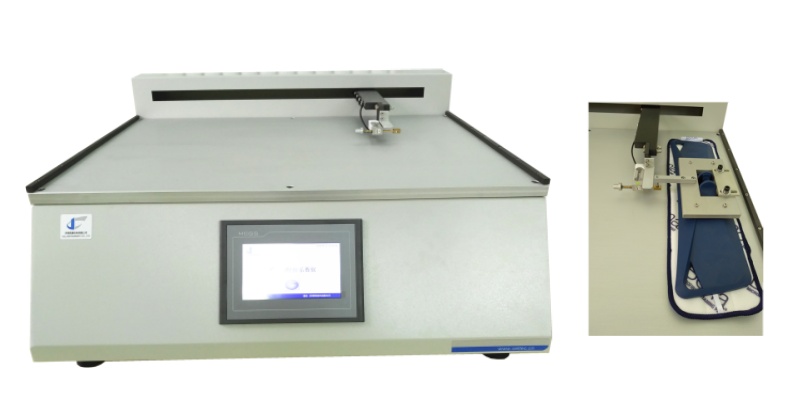

Itu Penguji Koefisien Gesekan Kain Pel terutama digunakan untuk menilai sifat gesekan bahan pembersih seperti bantalan pel mikrofiber, pel spons dengan blok busa (baik selulosa, karet, atau plastik), dan bahan serupa lainnya. Bahan-bahan ini sangat bervariasi dalam sifatnya, jadi sangat penting untuk mengukur perilaku gesekannya dalam kondisi yang berbeda.

Aplikasi Uji COF Mop

Itu uji COF pel membantu produsen menentukan kinerja pel dalam skenario pembersihan di dunia nyata. Misalnya, pel dengan gesekan tinggi mungkin memerlukan tenaga lebih besar untuk mendorongnya, sehingga meningkatkan intensitas tenaga kerja. Di sisi lain, pel dengan gesekan rendah mungkin tidak mencengkeram permukaan secara efektif, sehingga menghasilkan hasil pembersihan yang buruk. Menyeimbangkan kedua hal ekstrem ini penting untuk memastikan kegunaan dan kinerja pembersihan pel.

Selain pengembangan produk, pengujian ini juga sangat berharga dalam jaminan kualitas. Produsen dan pemasok pel dapat menggunakan mesin uji kualitas pel untuk memverifikasi bahwa setiap kumpulan produk memenuhi standar industri untuk efisiensi pembersihan, daya tahan, dan keamanan.

Metodologi Uji untuk Pengujian COF Mop

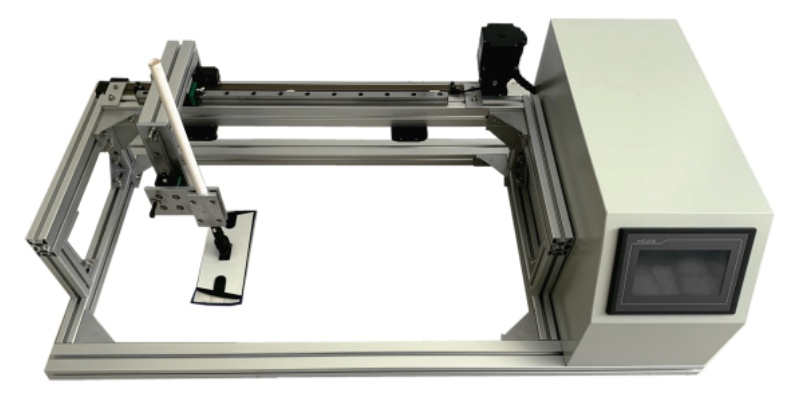

Proses untuk melakukan suatu Uji Koefisien Gesekan Kain Pel melibatkan beberapa langkah yang mudah namun penting. Berikut ini adalah penjelasan rinci tentang prosedurnya:

-

1. Persiapan Sampel:

Kain pel dipasang dengan hati-hati pada rangka aluminium atau plastik. Rangka membantu mengamankan kain pada tempatnya selama pengujian dan memastikan sampel terdistribusi secara merata. -

2. Pengaturan Pengujian:

Setelah sampel diamankan, seluruh bagian yang dirakit (termasuk kain pel dan rangkanya) diberi beban tertentu. Beban yang diberikan biasanya distandarisasi untuk mensimulasikan kondisi dunia nyata, guna memastikan bahwa hasil pengujian akurat dan dapat diandalkan. -

3. Pengukuran:

Kereta luncur, yang dilengkapi dengan permukaan datar (biasanya berukuran 100x100mm dan berat 225g ± 1g), kemudian ditarik melintasi kain pel dengan kecepatan konstan 500mm/menit sejauh 500mm. Selama proses ini, gaya yang dibutuhkan untuk menggerakkan kereta luncur diukur. Gaya ini dibandingkan dengan gaya tegak lurus yang diberikan oleh beban untuk menghitung koefisien gesekan.

COF statis (µs)

Ini mengukur gaya yang dibutuhkan untuk memulai gerakan. Ini mencerminkan hambatan gesekan yang harus diatasi untuk memulai proses pembersihan.

COF kinetik (µd)

Ini mengukur gaya yang dibutuhkan untuk mempertahankan gerakan saat kereta luncur bergerak. Ini membantu menilai gaya gesekan yang akan dialami selama pembersihan berkelanjutan.

Hasil pengukuran ini dicatat dan digunakan untuk mengevaluasi sifat gesekan kain pel. Dengan membandingkan nilai COF statis dan kinetik, produsen dapat lebih memahami bagaimana kain pel akan bekerja dalam kondisi nyata.

Spesifikasi Teknis

Itu Penguji Koefisien Gesekan Kain Pel dirancang dengan mengutamakan presisi dan fleksibilitas tinggi. Berikut ini adalah spesifikasi teknis utama perangkat tersebut:

| Parameter | Spesifikasi |

| Jangkauan Kekuatan | 100N |

| Resolusi | 0,5% FS-nya |

| Rentang Kecepatan | 1~1000mm/menit |

| Kecepatan Akurasi | 0,1 mm/menit |

| Ukuran Kereta Luncur | Ukuran 100x100 mm |

| Berat Kereta Luncur | 225 gram ± 1 gram |

| Berat Sampel | 520 gram ± 1 gram |

| Stroke | 500 mm |

| Tinggi Loadcell | 50 mm |

| Mode Uji | 5 kelompok |

| Catu Daya | Tegangan 110~220V |

Spesifikasi ini memungkinkan Penguji Koefisien Gesekan Kain Pel untuk memenuhi beragam kebutuhan produsen dan laboratorium pengujian, menyediakan pengukuran yang tepat dan akurat setiap saat.

Fitur Utama Mesin Uji Kualitas Pel

Itu Penguji Koefisien Gesekan Kain Pel menawarkan beberapa fitur canggih yang dirancang untuk menyediakan pengujian yang akurat dan andal bagi produsen dan tim kontrol kualitas. Berikut adalah beberapa fitur utama yang membedakan mesin ini:

Sistem ini menggunakan PLC (Programmable Logic Controller) untuk memastikan presisi tinggi dalam mengendalikan parameter pengujian. Layar HMI (Human-Machine Interface) menyediakan antarmuka intuitif bagi pengguna untuk memantau dan menyesuaikan pengaturan.

Kecepatan pengujian dapat disesuaikan dari 1 mm/menit hingga 1000 mm/menit, sehingga pengguna dapat mensimulasikan berbagai skenario di dunia nyata. Selain itu, alat penguji menawarkan berbagai parameter pengujian yang dapat disesuaikan untuk memenuhi berbagai bahan dan kebutuhan pel.

Dirancang untuk penggunaan jangka panjang, alat uji ini memberikan hasil yang dapat diandalkan bahkan di lingkungan yang menuntut. Alat ini ideal untuk penelitian dan pengembangan serta proses jaminan kualitas.

Dengan antarmuka yang sederhana dan mudah dipahami, bahkan mereka yang memiliki pengalaman teknis terbatas dapat mengoperasikannya mesin uji kualitas pel secara efektif.

FAQ tentang Penguji Efikasi Pembersihan

1. Untuk apa Alat Uji Koefisien Gesekan Kain Pel digunakan?

Penguji digunakan untuk mengukur koefisien gesekan kain pel, memastikan bahwa kain pel memberikan kinerja pembersihan yang optimal tanpa intensitas tenaga kerja yang berlebihan.

2. Apa perbedaan antara COF statis dan kinetik untuk uji COF pel?

COF statis mengukur gaya yang dibutuhkan untuk memulai gerakan pel, sementara COF kinetik mengukur gaya yang dibutuhkan untuk mempertahankan gerakan berkelanjutan selama pembersihan.

3. Apakah Penguji Koefisien Gesekan Kain Pel dapat digunakan untuk berbagai jenis kain pel?

Ya, penguji ini cocok untuk menguji berbagai bahan pel, termasuk pel mikrofiber dan spons.

4. Permukaan apa yang dapat diuji dengan Mesin Uji Mop COF?

Penguji dapat mensimulasikan berbagai kondisi pembersihan, termasuk permukaan basah, kering, dan berdebu.

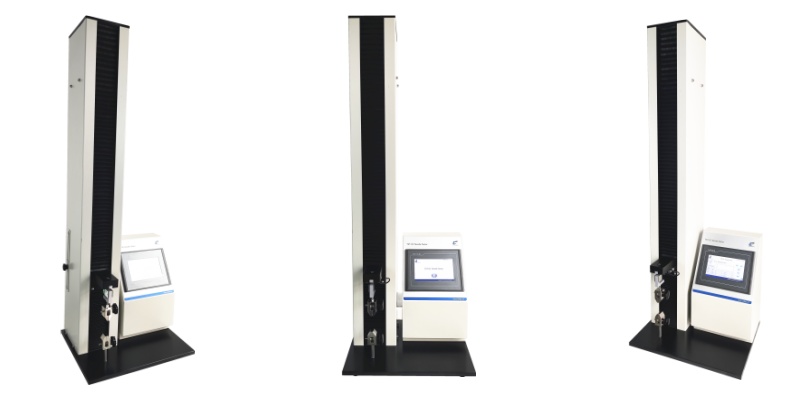

Solusi Kontrol Kualitas Pel Terkait

Mencari Penguji COF Mop yang andal?

Jangan lewatkan kesempatan untuk mengoptimalkan proses kontrol kualitas Anda dengan peralatan canggih.