BENVENUTI NEL NOSTRO BLOG

Articoli per il controllo della qualità del mocio in spugna

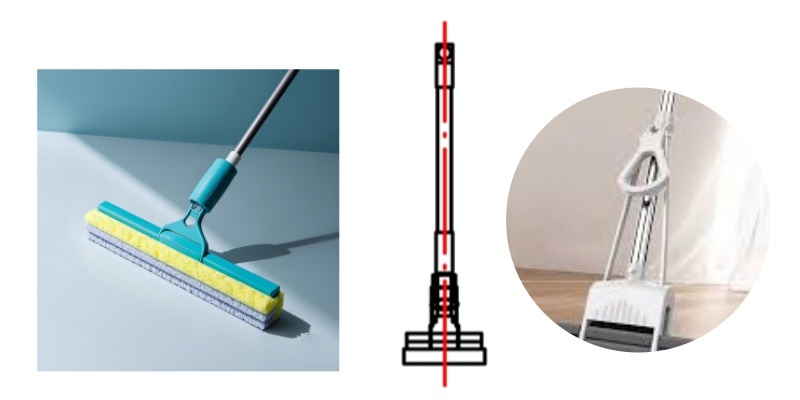

I mop spugna sono strumenti di pulizia essenziali utilizzati in ambito domestico, commerciale e industriale. La loro affidabilità dipende in larga misura dalla qualità dei materiali e dai processi di collaudo che ne verificano le prestazioni. Un programma di controllo qualità completo per i mop spugna assicura che siano durevoli, funzionali e sicuri da usare.

Quando si tratta del controllo di qualità del mocio spugna, vengono progettati diversi test critici per valutare i vari componenti del mocio, dalla testa del mocio al manico. Questi test assicurano che i mocio soddisfino gli standard di sicurezza e prestazioni, nonché le aspettative dei clienti in termini di durata.

1. Prova di fatica della testa del mocio in spugna

Il test di fatica è uno degli aspetti più importanti del controllo di qualità del mocio spugna, poiché simula l'uso continuo a cui è sottoposta una testa del mocio durante le attività di pulizia. Questo test valuta la durata della testa della spugna, in particolare la sua capacità di resistere a movimenti ripetitivi senza guasti.

Metodo di prova:

- La testa del mocio viene immersa completamente nell'acqua per garantire che la spugna sia completamente satura.

- Il mocio viene quindi utilizzato per eseguire ripetutamente un'azione di spremitura dell'acqua. Ciò imita il movimento di spremitura dell'acqua dalla spugna durante la normale pulizia.

- Il mocio viene sottoposto a 3.000 cicli di questa azione per simulare un utilizzo prolungato.

- Dopo aver completato il test, la testa del mocio viene ispezionata per rilevare eventuali segni di usura, tra cui crepe, distacchi o perdita di potere assorbente.

Questo test è fondamentale per determinare se lo straccio in spugna può resistere a un uso prolungato senza deteriorarsi nelle prestazioni. I risultati forniscono informazioni sui materiali utilizzati nella testa dello straccio e sulla qualità complessiva della costruzione.

2. Resistenza alla flessione del manico del mocio

Il manico di uno straccio in spugna svolge un ruolo cruciale nel garantire che l'utensile sia robusto e comodo da usare. Uno dei test più importanti per il manico è il test di resistenza alla flessione, che valuta la resistenza del manico alla flessione e la sua capacità di mantenere l'integrità strutturale sotto pressione.

Metodo di prova:

- Il manico telescopico viene esteso alla sua massima lunghezza e posizionato orizzontalmente, con entrambe le estremità fissate in posizione.

- Un peso da 5 kg è appeso al centro del manico esteso. Questo simula il carico che il manico può trasportare quando un utente applica forza al mocio.

- La maniglia viene quindi mantenuta in questa posizione per cinque minuti e i risultati vengono osservati attentamente per valutare la capacità della maniglia di sopportare il peso senza piegarsi o rompersi.

Questo test aiuta i produttori a determinare se il manico del mocio è in grado di resistere alle sollecitazioni fisiche a cui si va incontro durante le operazioni di pulizia, assicurando che non si pieghi o si rompa durante l'uso.

3. Resistenza del manico telescopico del mocio

Un manico telescopico per mocio consente lunghezze regolabili, offrendo maggiore flessibilità e comfort durante l'uso. La resistenza del manico telescopico è fondamentale per evitare rotture o malfunzionamenti quando gli utenti ne regolano la lunghezza.

Metodo di prova:

- La maniglia è fissata nella sua posizione estesa e viene applicata una forza di trazione di 150 N lungo la sua direzione assiale.

- In un altro test, viene applicata una forza di trazione di 70 N nella direzione opposta alla maniglia fissa per 10 secondi, testando la resistenza dei componenti che tengono insieme la maniglia.

Questi test sono essenziali per garantire che il manico telescopico del mocio possa sopportare le sollecitazioni dell'uso quotidiano, rimanere funzionale nel tempo e prevenire problemi di sicurezza per gli utenti.

Questi test possono essere realizzati in modo efficiente utilizzando un macchina per prove di trazione personalizzata, che offre risultati precisi e affidabili per valutare la resistenza, la durata e le prestazioni di materiali come manici di mocio in spugna, teste di mocio e altri componenti. A macchina per prove di trazione personalizzata consente ai produttori di personalizzare i parametri di prova per soddisfare requisiti specifici del prodotto, come la regolazione della capacità di carico, la velocità di prova e la configurazione della presa. Questa flessibilità garantisce che la macchina possa simulare accuratamente le condizioni del mondo reale, dai test di fatica alle valutazioni della forza di trazione. Incorporando un macchina per prove di trazione personalizzata Grazie al processo di controllo qualità, i produttori possono garantire che i loro prodotti soddisfano i più elevati standard di resistenza e affidabilità, il che si traduce in un miglioramento delle prestazioni del prodotto e della soddisfazione del cliente.