SVEIKI Į MŪSŲ BLOGĄ

Šluostės galvutės audinio COF testavimas

Mop Lab kokybės kontrolė

Šluostės galvučių audinio COF bandymas yra labai svarbus vertinant šluotų galvučių veikimą ir ilgaamžiškumą realiomis valymo sąlygomis. Šis procesas matuoja šluotų galvučių medžiagų trinties koeficientą (COF), kuris tiesiogiai veikia jų gebėjimą sklandžiai judėti įvairiais paviršiais.

Išnagrinės COF testavimo svarbą, naudojamus metodus ir kaip jis prisideda prie šluotų kokybės ir efektyvumo gerinimo.

Kas yra šluostės galvutės audinio COF bandymas?

Trinties koeficientas (COF) yra pagrindinis rodiklis, rodantis, kaip gerai šluotos galvutė juda per grindis ar paviršius naudojimo metu. COF bandymas apima jėgos taikymą šluostės galvutei ir pasipriešinimo, su kuriuo ji susiduria tempiant paviršių, matavimą. Rezultatai lemia audinio gebėjimą sklandžiai slysti, o tai yra esminis veiksnys, užtikrinantis efektyvų valymo efektyvumą.

Įvairios šluotos medžiagos turi skirtingą trinties lygį, priklausomai nuo tokių veiksnių kaip audinio sudėtis, drėgmės sulaikymas ir paviršiaus tekstūra. Išbandydami šluotų galvučių COF, gamintojai gali optimizuoti savo gaminius, kad užtikrintų patvarumo ir našumo pusiausvyrą. Šluostės galvutės audinio COF testavimas yra neatsiejama gaminio kūrimo, kokybės kontrolės ir nuoseklumo dalis.

Mop Lab kokybės kontrolė – šluostės galvutės audinio COF testavimo svarba

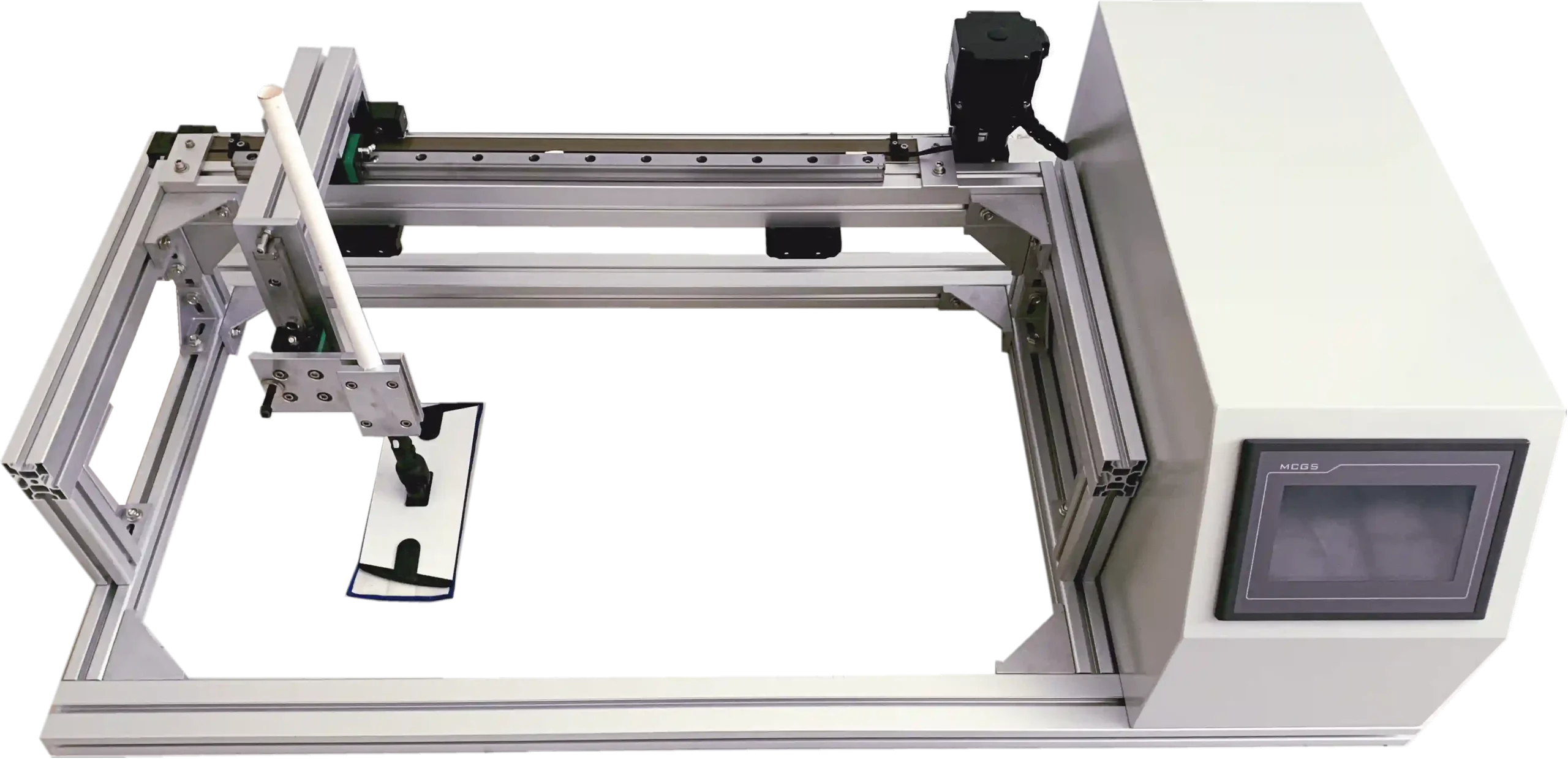

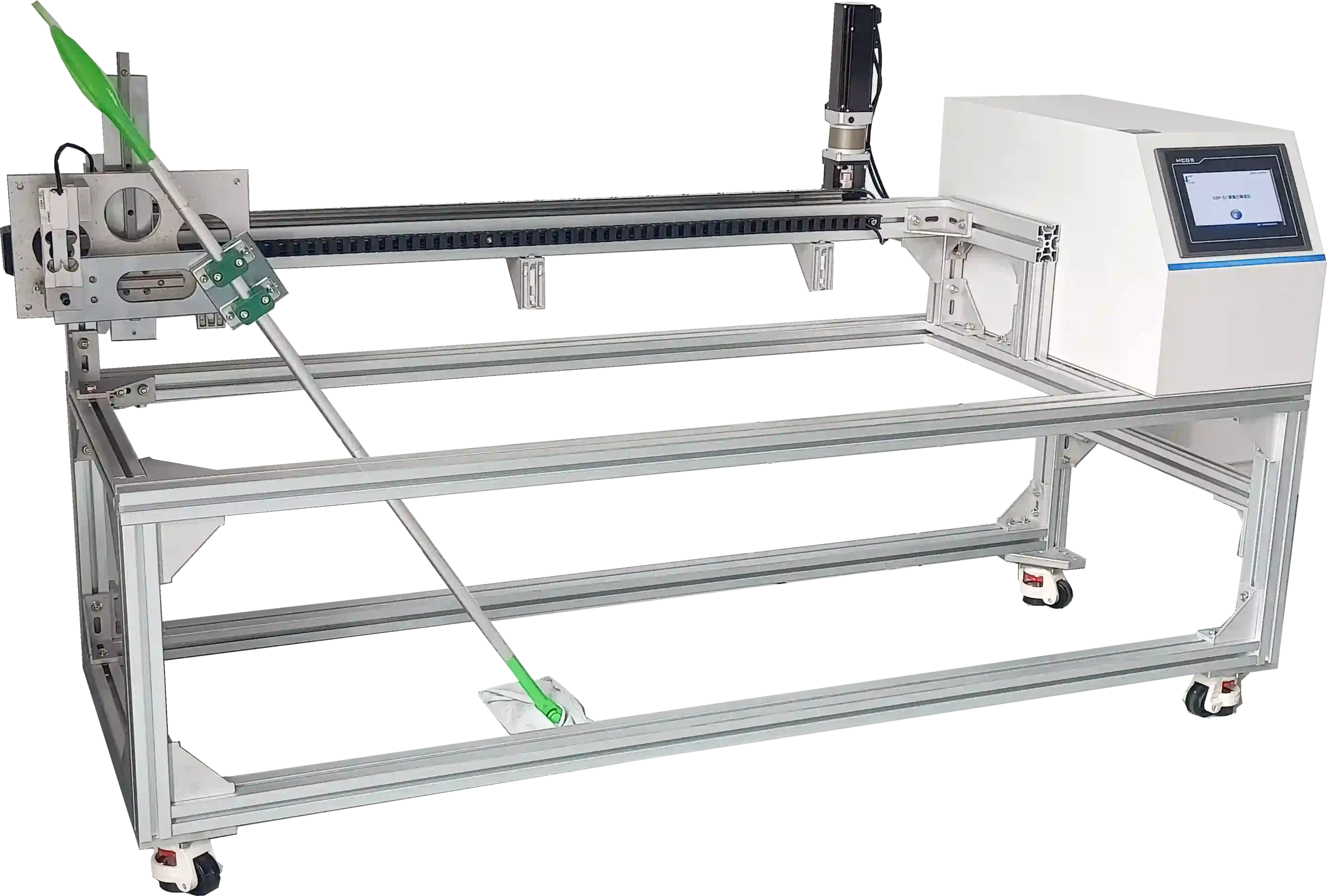

Šluostės galvutės audinio COF testavimas atlieka pagrindinį vaidmenį išlaikant aukštos kokybės standartus gaminant valymo įrangą. Kokybės kontrolės laboratorijos atlieka šį bandymą, siekdamos užtikrinti, kad šluotų galvutės būtų veiksmingos ir patvarios realiame pasaulyje. Naudojant a trinties koeficiento testeris, gamintojai gali įvertinti, kaip lengvai jų šluotų galvutės juda per grindis, atsižvelgdami į įvairius kintamuosius, kurie gali turėti įtakos valymo efektyvumui.

Didėjant patikimų, ilgalaikių valymo sprendimų paklausai, tikslaus COF testavimo reikšmė tampa vis akivaizdesnė. Rezultatai leidžia gamintojams tiksliai sureguliuoti šluotų galvučių dizainą ir medžiagų sudėtį, kad būtų užtikrintas optimalus veikimas skirtingomis valymo sąlygomis.

Mop COF testavimo metodas: žingsnis po žingsnio procesas

Siekiant užtikrinti nuoseklumą ir patikimumą, atliekant šluotos galvutės audinio COF bandymą, paprastai atliekami šie veiksmai:

1. Bandomųjų mėginių paruošimas

Prieš pradedant bandymą, parenkamas reprezentatyvus šluotos galvutės audinio pavyzdys. Šis pavyzdys turi atitikti galutiniame produkte naudojamą medžiagos sudėtį ir tekstūrą.

2. Bandymo paviršiaus parinkimas

Paviršius, ant kurio bus tikrinama šluotos galvutė, parenkamas kruopščiai. Šis paviršius gali skirtis priklausomai nuo numatomos valymo aplinkos, pavyzdžiui, lygių grindų, plytelių ar tekstūruotų paviršių. COF gali keistis atsižvelgiant į paviršiaus charakteristikas.

3. Įrangos kalibravimas

Trinties koeficiento testeris sukalibruotas taip, kad būtų užtikrintas tikslus ir nuoseklus rezultatas. Kalibravimas užtikrina, kad prietaisas teisingai išmatuotų šluotos galvutės jėgą ir atitinkamą pasipriešinimą.

4. Jėgos taikymas

Testeris naudoja žinomą jėgą šluostės galvutei, judindamas ją tam tikru greičiu per paviršių. Jėga matuojama, kai ji įveikia trintį tarp šluotos audinio ir paviršiaus, todėl gaunamas tikslus COF rodmuo.

5. Duomenų rinkimas ir analizė

Gauti duomenys renkami ir analizuojami. Didesnė COF reiškia didesnę trintį, todėl valymui gali prireikti daugiau pastangų, o mažesnis COF rodo lengvesnį judėjimą. Abu kraštutinumai gali būti problemiški, nes per didelė trintis gali lemti ankstyvą šluotos galvutės nusidėvėjimą, o per maža trintis gali pakenkti valymo efektyvumui.

6. Galutinė ataskaita

Tada bandymų rezultatai yra dokumentuojami, gamintojui suteikiant įžvalgų apie jų šluotos galvutės audinio veikimą. Šioje ataskaitoje pateikiami gaminio patobulinimai, užtikrinantys, kad šluotų galvutės atitiktų norimus patvarumo ir naudojimo standartus.

Šluostės galvutės audinio COF bandymas kokybės užtikrinimo srityje

Veiksmingas šluostės galvutės audinio COF bandymas palaiko platesnį šluotų gamybos kokybės užtikrinimo tikslą. Reguliariai tikrindami COF, gamintojai gali užtikrinti, kad jų gaminiai atitiktų pramonės standartus dėl našumo ir ilgaamžiškumo. Šis bandymas yra ypač svarbus siekiant užtikrinti, kad šluostės galvutės išliktų veiksmingos laikui bėgant, užtikrindamos pastovią valymo galią ir išlaikant pusiausvyrą tarp lengvo judėjimo ir valymo efektyvumo.

Šluostės galvutės audinio COF testavimo pranašumai

- Patobulintas našumas: Testavimas padeda gamintojams nustatyti optimalų COF efektyviam valymui, sumažinant naudotojams reikalingų pastangų kiekį.

- Padidintas patvarumas: Suprasdami, kaip audinių medžiagos veikia trinties sąlygomis, gamintojai gali sukurti šluotų galvutes, kurios atsparios dilimui ir tarnauja ilgiau.

- Ekonomiškumas: Tikslus testavimas padeda išvengti brangiai kainuojančių gaminio gedimų ir klientų skundų, užtikrinant, kad šluostės galvutės gerai veiktų visą jų naudojimo laiką.

- Nuolatinė kokybė: Reguliarus COF testavimas garantuoja, kad kiekviena šluotų galvučių partija atitinka norimus standartus, išlaikant produkto kokybės nuoseklumą.

Norite pagerinti savo šluotų gaminio našumą?

Susisiekite su „Cell Instruments“ šiandien ir sužinokite daugiau apie mūsų tikslumo trinties koeficiento testerius ir kaip jie gali optimizuoti jūsų šluotos galvutės audinio kokybės kontrolę.

Ląstelių instrumentai

Gamintojas ir gamykla

Prisijunkite prie mūsų ir gaukite geriausią šluotų kokybės laboratorinių tyrimų sprendimą

DUK apie šluostės galvutės audinio COF testavimą

COF arba trinties koeficientas matuoja šluotos galvutės audinio atsparumą judant per paviršių. Mažesnis COF rodo sklandesnį judėjimą, o didesnis COF rodo didesnį pasipriešinimą.

Bandymas apima šluostės galvutės audinio mėginio vilkimą per iš anksto nustatytą paviršių, veikiant žinoma jėga. Trinties varža matuojama siekiant nustatyti COF.

COF bandymas padeda užtikrinti, kad šluotų galvutės sklandžiai slystų paviršiais, o tai pagerina valymo efektyvumą ir sumažina audinio ir grindų paviršiaus nusidėvėjimą.

Taip, COF testavimas yra plačiai naudojamas valymo pramonėje, siekiant įvertinti įvairių valymo priemonių, įskaitant šluostes, šepečius ir kitus paviršių valymo produktus, veikimą.