Mop wrijvingskrachttester

Beste tester voor

– Mop Kwaliteitsborgingstesten

Moppen zijn essentiële schoonmaakmiddelen voor zowel residentiële als commerciële toepassingen. Hun effectiviteit en gebruikerscomfort hangen sterk af van hun wrijvingsprestaties. De Mop wrijvingskrachttester is een gespecialiseerd instrument dat is ontworpen om de wrijvingskracht van verschillende dweilen nauwkeurig te meten, wat zorgt voor superieure reinigingsefficiëntie en duurzaamheid. Met deze tester kunnen fabrikanten strenge dweilkwaliteit testen, het optimaliseren van hun ontwerpen en het verbeteren van de productkwaliteit om aan de verwachtingen van de klant te voldoen.

Het belang van dweilwrijvingstesten

Wrijving speelt een cruciale rol bij het bepalen van de schoonmaakeffectiviteit van een dweil. Hoge wrijving kan de schoonmaak verbeteren, maar kan ook leiden tot overmatige vermoeidheid bij gebruikers, terwijl lage wrijving de schoonmaakkwaliteit in gevaar kan brengen. Dweilen die zijn gemaakt van verschillende materialen, ontwerpen en productietechnieken vertonen verschillende wrijvingseigenschappen. Juiste kwaliteitscontrole van dweilen Door middel van gestandaardiseerde tests wordt gegarandeerd dat producten de juiste balans bieden tussen reinigingsprestaties en gebruikerscomfort.

Door gebruik te maken van de Mop wrijvingskrachttesterkunnen fabrikanten vol vertrouwen producten leveren die voldoen aan strenge kwaliteitsborgingstesten normen, waardoor klachten van klanten afnemen en het vertrouwen in het merk wordt versterkt.

Items van Mop Wrijvingskracht Testen

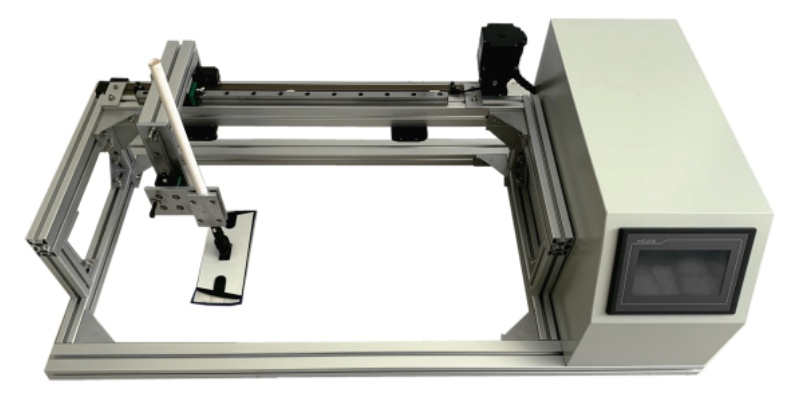

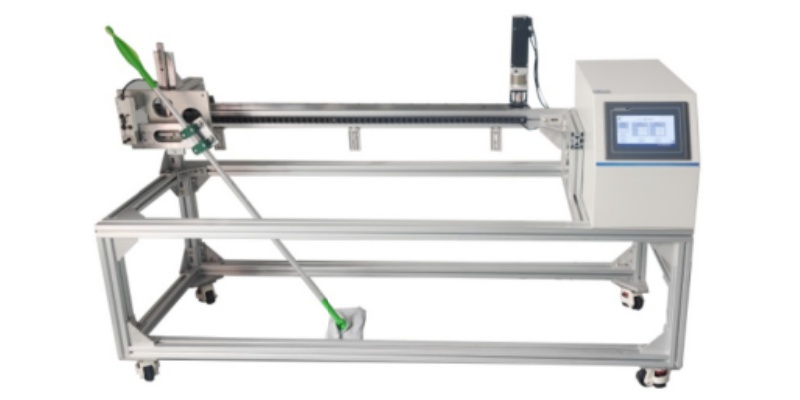

De Mop wrijvingskrachttester werkt door de wrijvingskracht te meten die wordt uitgeoefend door een dweil onder gecontroleerde omstandigheden. De test omvat:

- Heen en weer gaande beweging: Het dweilmonster wordt onderworpen aan herhaalde heen-en-weerbewegingen onder een specifieke belasting.

- Variabele snelheden: De wrijvingskracht wordt bij verschillende bewegingssnelheden gemeten, waardoor realistische gebruiksscenario's worden gesimuleerd.

- Bidirectionele meting: De wrijving wordt in beide richtingen gemeten binnen één testcyclus om een uitgebreide analyse te garanderen.

Het apparaat gebruikt een uiterst nauwkeurige loadcell om realtime wrijvingskrachtwaarden te registreren en weer te geven. Deze gegevens dienen als wetenschappelijke basis voor het evalueren van mopprestaties, waardoor fabrikanten ontwerpfouten kunnen identificeren, nieuwe materialen kunnen testen en de algehele productefficiëntie kunnen verbeteren.

Technische specificaties

De Mop wrijvingskrachttester is uitgerust met geavanceerde functies die nauwkeurige en efficiënte tests garanderen:

- 1. Intuïtieve gebruikersinterface::Een 7-inch touchscreen Human-Machine Interface (HMI) biedt een gebruiksvriendelijke ervaring met intuïtieve navigatie.

- 2. Hoognauwkeurige lastcel: betrouwbare en herhaalbare testresultaten.

- 3. Instelbare testsnelheid:Snelheden van 1 tot 60.000 mm/min maken veelzijdige tests mogelijk om verschillende reinigingsomstandigheden te simuleren.

- 4. Weergave van realtime gegevens:De wrijvingskracht wordt in realtime weergegeven, zodat operators de tests kunnen controleren en indien nodig kunnen aanpassen.

- 5. Mobiliteit:Het apparaat is voorzien van wieltjes, waardoor het eenvoudig te verplaatsen en in te zetten is in verschillende testomgevingen.

- 6. Aanpasbare parameters: Speciaal ontworpen voor moppen van verschillende afmetingen en materialen, wat flexibiliteit biedt voor uiteenlopende testvereisten.

Technische specificaties

Parameter | Details |

Meetbereik | Tot 200N (aanpasbaar) |

Nauwkeurigheid testen | ±0,5% FS |

Snelheidsbereik | 1–60.000 mm/min |

Maximale laadcapaciteit | 10kg |

Monsterhoogtebereik | 1.000–1.500 mm |

Klemhoek | Verstelbaar tussen 45°–60° |

Basisbewegingsslag | 1.000mm |

Stroomvoorziening | 110–220V |

Mopkwaliteitstesten

Toepassingen van Tester

De Mop wrijvingskrachttester bedient een breed scala aan industrieën, waaronder:

Fabrikanten van schoonmaakproducten

Evalueer en verfijn dweilontwerpen om de schoonmaakprestaties te verbeteren.

Kwaliteitscontrole-instanties

Zorg ervoor dat producten voldoen aan de regelgeving en prestatie-eisen.

R&D-laboratoria

Test innovatieve materialen en ontwerpen om de grenzen van schoonmaakefficiëntie te verleggen.

Met behulp van deze tester kunnen fabrikanten superieure mop kwaliteitsborgingstesten, waardoor productiefouten worden verminderd en hun producten voldoen aan de behoeften van de klant.

Betekenis van het testproces

Het testproces biedt kritisch inzicht in:

Materiaalprestaties

Evalueert hoe verschillende dweilmaterialen presteren onder verschillende omstandigheden.

Duurzaamheidstesten

Beoordeelt de betrouwbaarheid van de dweil op lange termijn door herhaald gebruik te simuleren.

Ontwerpvalidatie

Bevestigt de effectiviteit van ontwerpwijzigingen om de prestaties te verbeteren.

Deze systematische aanpak van dweilkwaliteit testen zorgt ervoor dat fabrikanten hoogwaardige, gebruiksvriendelijke producten leveren en zo de tevredenheid en loyaliteit van klanten bevorderen.

Veelgestelde vragen over de Mop Friction Force Tester

Het instrument kan een breed scala aan dweilen testen, waaronder microvezel-, katoenen, spons- en synthetische varianten.

Door nauwkeurige, realtime gegevens over de wrijvingsprestaties te leveren, helpt de tester fabrikanten bij het optimaliseren van mopmaterialen en -ontwerpen voor superieure kwaliteit.

Ja, de instelbare snelheids- en belastingparameters bootsen de werkelijke reinigingsomstandigheden na voor nauwkeurige resultaten.

Absoluut. De tester voldoet aan strenge kwaliteitsborgingsnormen, wat betrouwbare en herhaalbare testresultaten garandeert.

Bidirectionele tests zorgen voor een uitgebreide analyse door wrijvingskrachten vast te leggen bij zowel voorwaartse als achterwaartse bewegingen, waardoor het gebruik in de echte wereld wordt gesimuleerd.

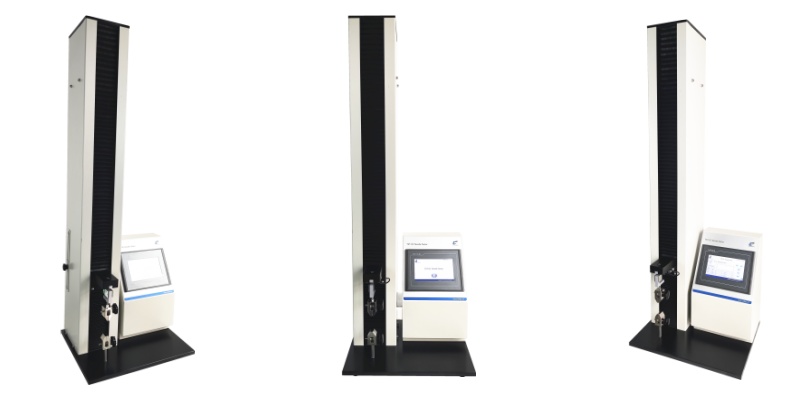

Gerelateerde Mop Kwaliteitscontrole Oplossing

Bent u op zoek naar een betrouwbare machine om de kwaliteit van dweilen te testen?

Mis de kans niet om uw kwaliteitscontroleprocessen te optimaliseren met ultramoderne apparatuur.