BEM-VINDO AO NOSSO BLOG

Solução de controle de qualidade de esfregão

Instrumento de teste de esfregão

Os esfregões desempenham um papel essencial na manutenção da limpeza em residências, escritórios e espaços industriais. Sua eficácia impacta diretamente na eficiência da limpeza e na satisfação do usuário. Para garantir que os esfregões atendam aos padrões de alto desempenho, os fabricantes devem implementar soluções rigorosas de controle de qualidade de esfregões. Avançado instrumentos de teste de esfregão, incluindo MopFric-01 Testador de força de atrito de esfregão, LIMPO-EFF01 Testador de Eficácia de Limpeza, e COF-S1 Testador de coeficiente de atrito de pano de esfregão, fornecem os dados necessários para otimizar o design e a funcionalidade.

Teste de força de atrito - Otimizando a eficiência da limpeza

Fundo

O atrito desempenha um papel fundamental na eficácia da limpeza de um esfregão. Enquanto o atrito adequado melhora a remoção de sujeira, o atrito excessivo pode aumentar a fadiga do usuário. Os esfregões feitos de vários materiais, designs e acabamentos exibem diferentes características de atrito. A avaliação dessas propriedades garante que o desempenho do esfregão seja equilibrado e adequado para diversas aplicações.

Aplicativo

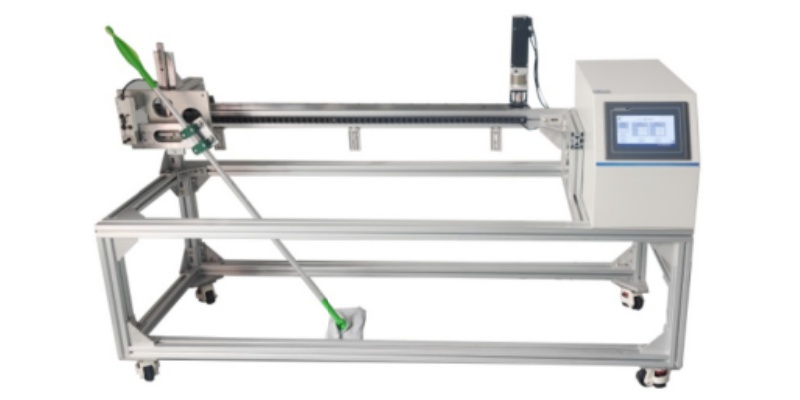

O MopFric-01 Testador de fricção de esfregão é projetado para medir as forças de atrito experimentadas durante o uso do esfregão. Este instrumento avalia como um esfregão interage com diferentes superfícies sob condições de carga e velocidades de movimento específicas. Ele captura forças de atrito bidirecionais em um único ciclo de teste, oferecendo resultados precisos e confiáveis.

Propósito e significado

- Aumenta a eficiência da limpeza garantindo níveis ideais de atrito.

- Reduz o esforço físico dos usuários, resultando em maior satisfação.

- Fornece aos fabricantes dados valiosos para melhorar os designs e materiais dos esfregões.

Metodologia de teste

- Um esfregão de amostra é posicionado no testador.

- O instrumento simula movimento para frente e para trás sob cargas e velocidades controladas.

- Dados em tempo real são registrados usando uma célula de carga de alta precisão, que mede as forças de atrito.

- Os resultados são analisados para determinar se o esfregão atende aos padrões de desempenho.

Use Simulate - Replicando cenários do mundo real

Fundo

O desempenho de um esfregão depende de sua capacidade de lidar com várias superfícies e contaminantes de forma eficaz. Simular cenários de limpeza do mundo real permite que os fabricantes avaliem as capacidades de um esfregão de forma abrangente.

Aplicativo

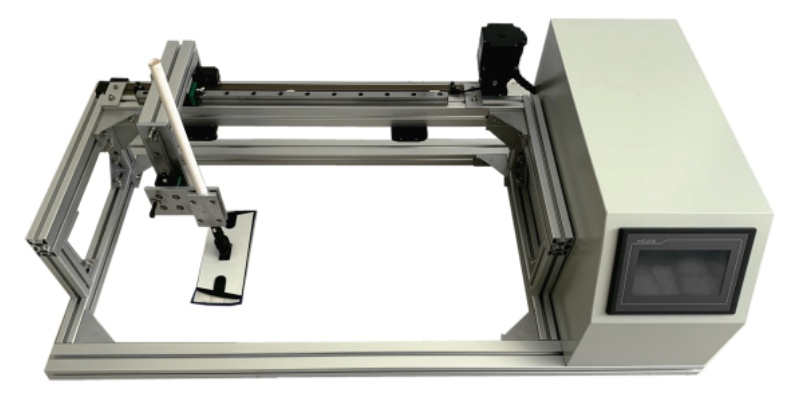

O CLEAN-EFF01 Testador de eficácia de limpeza é uma ferramenta avançada que avalia o desempenho de limpeza de esfregões, panos e trapos. Ela replica o uso na vida real em superfícies como azulejos, pisos de madeira e vidro, garantindo que o produto tenha um desempenho ideal em todos os ambientes.

Propósito e significado

- Fornece insights sobre o desempenho de um esfregão em diversas superfícies.

- Melhora os processos de controle de qualidade, resultando em maior confiabilidade do produto.

- Auxilia no desenvolvimento de soluções de limpeza inovadoras e eficientes.

Metodologia de teste

- O material de limpeza é preso a uma estrutura de alumínio ou plástico.

- A estrutura é montada em um braço móvel posicionado verticalmente sobre a superfície de teste.

- Parâmetros como pressão aplicada, velocidade de movimento e contagem de ciclos são ajustados para simular condições de limpeza realistas.

- Avaliações pós-teste são conduzidas para avaliar a eficácia da limpeza e a durabilidade do material.

Teste COF: equilibrando usabilidade e eficácia

Fundo

O coeficiente de atrito (COF) é um fator crítico que influencia a usabilidade e o desempenho de limpeza de um esfregão. Mops com atrito excessivo aumentam a intensidade do trabalho, enquanto atrito insuficiente prejudica a eficiência da limpeza. Alcançar um COF ideal é crucial para manter o equilíbrio entre esses dois extremos.

Aplicativo

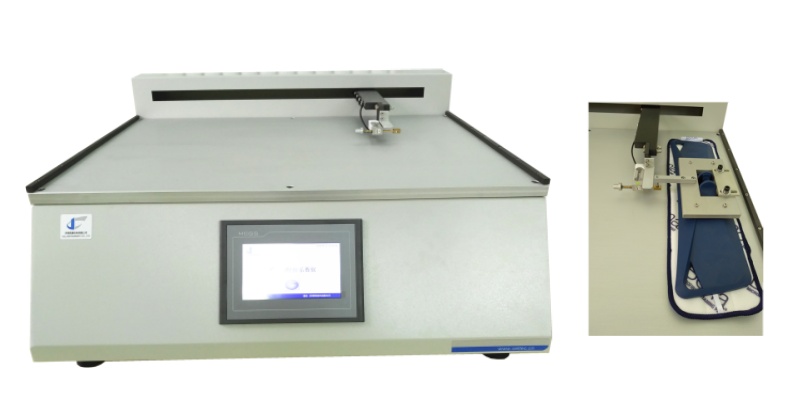

O Testador COF-S1 é feito sob medida para materiais de esfregão, incluindo almofadas de microfibra e blocos de esponja. Ele avalia o desempenho de fricção em superfícies secas, molhadas e empoeiradas, garantindo a adaptabilidade do esfregão a diversas tarefas de limpeza.

Metodologia de teste

- Os materiais do esfregão são testados sob condições controladas em diversas superfícies.

- O COF-S1 mede a resistência gerada durante o movimento do esfregão.

- Os dados são analisados para identificar se os níveis de atrito estão dentro de faixas aceitáveis.

Propósito e significado

- Garante que os esfregões mantenham um desempenho consistente em diferentes ambientes.

- Ajuda os fabricantes a projetar produtos fáceis de usar que equilibram atrito e eficiência de limpeza.

- Contribui para o desenvolvimento de ferramentas de limpeza duráveis e confiáveis.

Benefícios do teste abrangente de esfregão

- Desempenho de limpeza aprimorado: Os testes garantem que os esfregões atendem a altos padrões de eficiência e usabilidade.

- Durabilidade aprimorada: Os processos de controle de qualidade identificam possíveis fraquezas, resultando em produtos mais confiáveis.

- Melhor satisfação do usuário: Os designs otimizados reduzem a fadiga do usuário e melhoram a experiência geral de limpeza.

- Fabricação com boa relação custo-benefício: A identificação precoce de falhas de projeto minimiza perdas de produção e aumenta a lucratividade.

- Vantagem competitiva:Testes rigorosos ajudam os fabricantes a se destacarem no mercado, entregando produtos superiores.