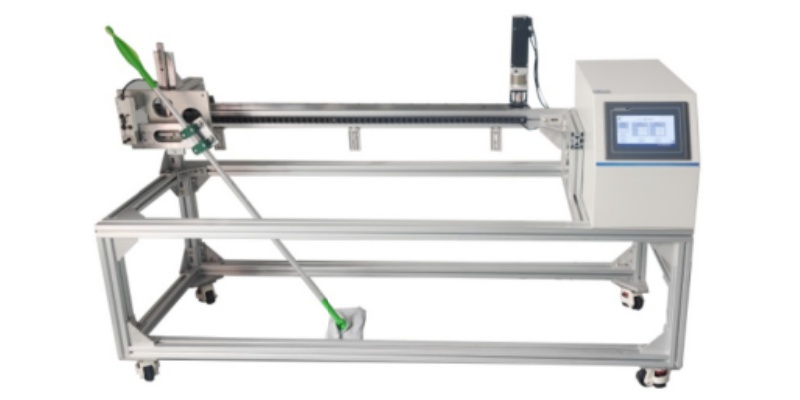

İplik Termal Büzülme Test Cihazı

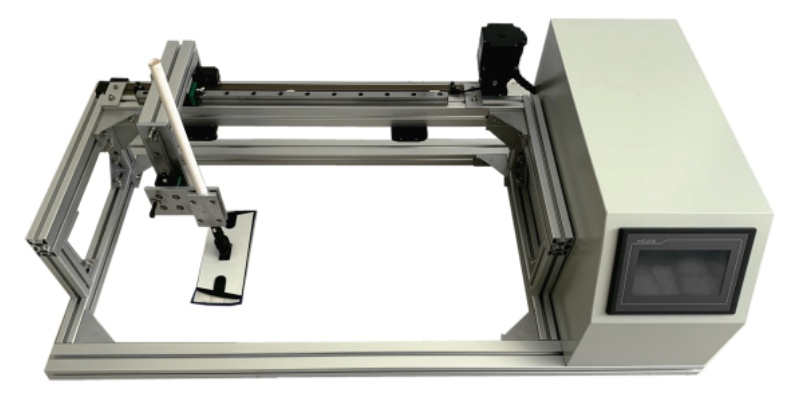

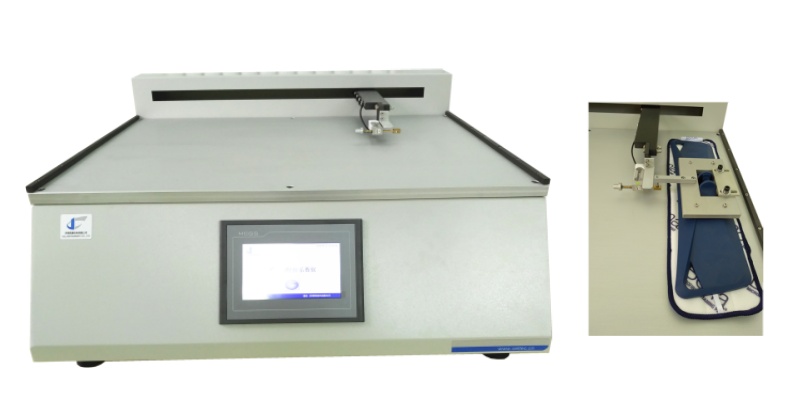

Paspas Malzeme Testi

-Isı Büzülme Testi

İplik Termal Büzülme Testi, iplik ürünlerinin üretim ve son kullanım süreçleri boyunca iyi performans gösterdiğinden emin olmak için çok önemlidir. Malzeme (iplik veya kumaş) paspaslama için kullanılacaksa, ASTM D4974'e göre İplik Termal Büzülme Testi daha da önemli hale gelir.

Paspas Malzemeleri için Termal Büzülme Testinin Önemi

Paspas endüstrisinde, paspas başlıklarında kullanılan iplikler sıklıkla sıcak suya ve diğer sert temizlik maddelerine maruz kalır. Bu maruziyet ipliğin büzülmesine neden olarak paspasın etkinliğini ve ömrünü etkileyebilir.

Büzülme Testi Neden Önemlidir?

Polyester ve naylon gibi malzemelerden yapılan iplikler ısıya maruz kaldığında büzülebilir ve bu da paspas malzemesinin yapısını tehlikeye atabilir. Termal büzülme testi, ipliklerin ve kordonların boyutsal kararlılıklarını koruyarak şu gibi sorunları önler:

- Azaltılmış paspas kapsama alanı

- Azalmış temizleme verimliliği

- Paspas başlığının kullanım ömrü kısaldı

İplik Termal Büzülme Test Cihazı Teknik Özellikleri

| Kullanım koşulları | -10~+40℃, RH: 45%~85%, titreşim yok |

| Sıcaklık Aralığı ve Doğruluk | Ortam~250°C; ±0,1°C |

| Büzülme Çözünürlüğü | 0.01% (100% 250mm'dir) |

| Büzülme Kuvveti Çözünürlüğü | 0,01N |

| Büzülme Kuvveti Aralığı | 0~50N (Özelleştirme Mevcuttur) |

| Test zamanı | 0.1~60dk |

| Güç | AC220V, 50Hz |

| Maksimum Isıtma Gücü | 1000W |

Neden ısıl büzülme testine ihtiyaç vardır?

Deformasyonu Önlemek

Paspaslar genellikle malzemenin yüksek emiciliğe sahip olmasını ve fırçalama verimliliği için şeklini korumasını gerektirir. Termal büzülme, kumaşın eşit olmayan bir şekilde büzülmesine, buruşmaya veya deformasyona neden olabilir. Test, ipliğin ısıya maruz kaldığında öngörülebilir şekilde davrandığından emin olarak bu sorunları önler.

Geliştirilmiş Uzun Ömür

Yüksek sıcaklıklara, temizleme solüsyonlarına ve mekanik aşınmaya düzenli olarak maruz kalmak kumaşın formunu kaybetmesine neden olabilir. Büzülme, liflerin gevşemesine ve daha hızlı aşınma ve yıpranmaya yol açabilir. Üreticiler, termal büzülme açısından test edilmiş iplik kullanarak, zorlu temizlik koşulları altında daha uzun süre dayanan daha dayanıklı paspaslar üretebilirler.

Müşteri Memnuniyeti

Müşteriler için, yıkamadan sonra küçülen veya şeklini kaybeden bir paspas beklendiği gibi performans göstermeyecektir, bu da memnuniyetsizliğe ve artan değiştirme maliyetlerine yol açacaktır. Termal küçülme testi, üreticilerin paspasın zaman içinde amaçlanan boyutunu, şeklini ve işlevini korumasını sağlayarak müşteri şikayetlerini azaltmalarına ve ürünün itibarını iyileştirmelerine yardımcı olur.

Isı Altında Dayanıklılık

Paspaslar genellikle yüksek ısıya sahip ortamlarda (mutfaklar, endüstriyel alanlar veya hastaneler gibi) kullanılır ve iplik veya kumaş hem paspaslamanın mekanik stresine hem de yıkama veya kurutmanın ısısına dayanmalıdır. ASTM D4974 ile yapılan testler, üreticilerin ipliğin sıcak suya veya yüksek kurutma sıcaklıklarına maruz kaldığında mukavemetini ve yapısını koruduğunu doğrulamalarına yardımcı olur ve paspasın tutarlı bir şekilde performans göstermesini sağlar.

Yıkama Sonrası Boyutsal Stabilite

Paspaslar genellikle sık sık yıkanır ve yüksek sıcaklıklara maruz kalır (örneğin, dezenfeksiyon için sıcak su). Termal büzülme testi, malzemenin yıkamadan sonra önemli ölçüde büzülmeyeceğini, paspasın boyutunu ve temizlik etkinliğini koruyacağını garanti eder. Aşırı büzülme, paspası etkisiz hale getirebilir veya şeklinin bozulmasına neden olabilir, bu da performansını ve kullanım ömrünü etkiler.

Paspas Malzeme Testi ve Isı Büzülmesi

Paspas malzemeleri için, özellikle polyester ve naylon gibi sentetik iplikler içerenler için, paspas malzemesinin büzülme testi kritik öneme sahiptir. Paspas başlıkları, genellikle yüksek sıcaklıklarda sık sık yıkamaya tabi tutulur ve bu da liflerde önemli büzülmeye neden olabilir. Üreticiler, bir termal büzülme test cihazı kullanarak termal büzülme testleri gerçekleştirerek şunları yapabilir:

- Mop başlıklarında kullanılan ipliklerin ısıya dayanıklılığını belirleyin

- İpliklerin tekrarlanan yıkama döngülerinden sonra boyutlarını ve şekillerini koruduğundan emin olun

- Paspas malzemelerinin bileşimini ve kalitesini optimize ederek kullanım ömürlerini uzatın

- Bu işlem, son ürün olan paspas başlığının, büzülme nedeniyle işlevselliğini kaybetmeden zaman içinde etkili bir performans göstermesini sağlar.

Termal Büzülme Test Cihazı - ASTM D4974 Standardı

Isıl Büzülme Testinin Adım Adım Süreci (ASTM D4974)

- Örnek Hazırlama:Test başlamadan önce iplik veya kordon doğal haline getirilir.

- Test Kurulumu:Numune, termal büzülme test cihazı içerisinde kontrollü gerilim altında monte edilir.

- Isıya Maruz Kalma: İplik veya kordon, belirli bir süre boyunca düzenlenmiş bir sıcaklıkta kuru ısıya tabi tutulur.

- Ölçüm: Termal büzülme test cihazı, genellikle malzemenin orijinal uzunluğunun yüzdesi olarak ifade edilen büzülme oranını hesaplar.

- Sonuç Analizi:Sonuçlar, malzemenin termal büzülme kuvveti ve oranı hakkında değerli veriler sunarak, üreticilerin ipliğin veya kordonun ısıya maruz kalma altındaki performansını değerlendirmesine yardımcı olur.

Isı Büzülme Testi hakkında SSS

1. Termal büzülme test cihazı kullanılarak hangi tür malzemeler test edilebilir?

Termal büzülme test cihazı, naylon, polyester, aramid ve daha birçok malzemeden yapılmış çeşitli iplikleri ve kordonları test edebilir.

2. Isıl büzülme testinde ASTM D4974 ile ASTM D5591 arasındaki fark nedir?

ASTM D4974, kontrollü gerilim altında büzülme oranını ölçmeye odaklanırken, ASTM D5591, ısıya maruz kalmanın neden olduğu büzülme kuvvetini ölçer.

3. Termal büzülme test cihazı paspas malzemesi testindeki kusurları azaltmaya yardımcı olabilir mi?

Evet, termal büzülme testi, potansiyel büzülme sorunlarını erken tespit ederek üreticilerin zaman içinde tutarlı performans gösteren yüksek kaliteli paspas malzemeleri üretmesine yardımcı olur.

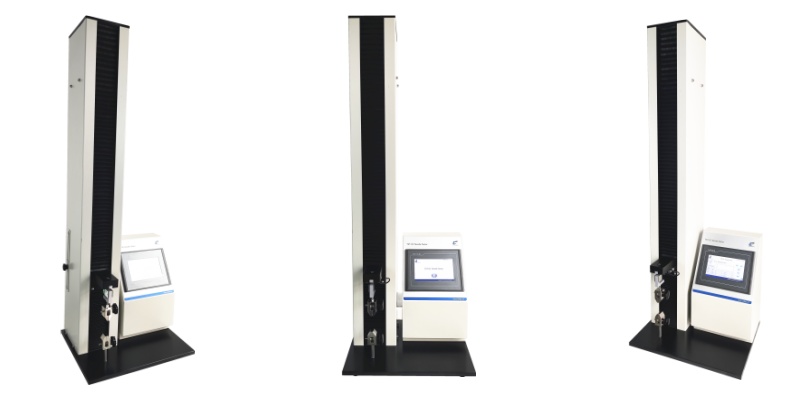

İlgili Paspas Kalite Kontrol Çözümü

Güvenilir İplik Termal Büzülme Test Cihazı mı arıyorsunuz?

Kalite kontrol süreçlerinizi son teknoloji ekipmanlarla optimize etme fırsatını kaçırmayın.