BLOGIMIZGA Xush kelibsiz

Mikrofiber mop sifatini nazorat qilish testi yechimi

Mikrofiber moplar o'zlarining yuqori tozalash ko'rsatkichlari uchun keng qo'llaniladi, ammo vaqt o'tishi bilan ularning samaradorligini saqlab qolish uchun qattiq sifat nazorati sinovi zarur. Mikrofiber mop sifatini tekshirish jarayoni materiallarning sanoat standartlariga muvofiqligini va kutilganidek ishlashini tasdiqlovchi bir nechta asosiy baholashlarni o'z ichiga oladi.

Biz mikrofiber mopning sifatini nazorat qilish sinovining ahamiyatini o'rganamiz, mikrofiber mopning qalinligi va mikrofiber paspasning qisqarishi sinovi kabi muhim sinovlarga e'tibor qaratamiz.

Nima uchun mikrofiber mop sifatini nazorat qilish juda muhim

Mikrofiber moplar chang, axloqsizlik va bakteriyalarni ushlab turish qobiliyati bilan baholanadi, bu ularni uy xo'jaliklaridan tortib tijorat joylarigacha bo'lgan ko'plab tozalash dasturlarida muhim vositaga aylantiradi. Biroq, tegishli sifat nazoratisiz, bu moplarning chidamliligi, ishlashi va umumiy ishonchliligi buzilishi mumkin. Shuning uchun ishlab chiqaruvchilar ishlab chiqarish jarayonida moplarning qalinligi, tolalar tarkibi, changni yutish qobiliyati va qisqarishi uchun zarur bo'lgan talablarga javob berishini ta'minlash uchun bir qator sinovlarni o'tkazishlari juda muhimdir.

Mikrofiber mop sifatini nazorat qilish quyidagilarga yordam beradi:

- Mopning barqaror ishlashi va uzoq umr ko'rishini ta'minlang.

- Materiallar va qurilish uchun sanoat standartlariga javob bering.

- Ishonchli, samarali mahsulotlarni yetkazib berish orqali mijozlar ehtiyojini qondirish darajasini oshiring.

- Ishlab chiqarish jarayonida mahsulot sifatiga ta'sir qilishi mumkin bo'lgan muammolarni aniqlang.

Asosiy mikrofiber mop sifatini nazorat qilish testlari

1. Mikrofiber mop qalinligi sinovi

Mikrofiber mop sifatini nazorat qilishning asosiy sinovlaridan biri bu qalinligi testidir. Mopning qalinligi uning changni yutish qobiliyati, chidamliligi va umumiy tozalash ko'rsatkichlarida muhim rol o'ynaydi. Juda yupqa mop namlikni samarali ushlab turmasligi mumkin, shu bilan birga juda qalin mopni ishlatish qiyin bo'lishi va quritish uchun ko'proq vaqt talab qilishi mumkin.

Qalinligini tekshirish tartibi:

- Mikrofiber mop materialining namunalari qalinligi bo'yicha qalinligi tekshirgich yordamida o'lchanadi. ASTM D1777.

- Mop ishlab chiqaruvchining dizayn xususiyatlariga mos kelishini ta'minlash uchun o'lchovlar belgilangan qalinlik standartlari bilan taqqoslanadi.

- Ushbu test ishlatilgan materialning sifatini aniqlashga yordam beradi va ishlab chiqarish jarayonidagi har qanday nomuvofiqliklarni ta'kidlashi mumkin.

Mikrofiber moplarning qalinligini sinab ko'rish barcha mahsulotlarda bir xil sifatni saqlab qolish, har bir mopning kutilganidek ishlashini ta'minlash uchun zarurdir.

2. Mikrofiber Mopning qisqarishini tekshirish

Mikrofiber mop sifatini nazorat qilishning yana bir muhim jihati qisqarish testidir. Siqilish, ayniqsa, dastlabki bir necha foydalanish va yuvish davrlaridan keyin, mopning ishlashi va mosligiga sezilarli ta'sir ko'rsatishi mumkin. Haddan tashqari qisqarish mopning tozalash samaradorligini pasayishiga va uning ishlash muddatining umumiy qisqarishiga olib kelishi mumkin.

Siqilish sinovi tartibi:

- Mikrofiber mopning tayyorlangan namunalari a issiqlik qisqarishi sinovi normal foydalanish ta'sirini simulyatsiya qilish. (ASTM D4974 va ASTM D5591 kabi)

- Mopning o'lchamlari yuvish jarayonidan oldin va keyin o'lchanadi.

- Siqilish ulushi sanoat standartlari yoki ishlab chiqaruvchi tomonidan belgilangan maqbul chegaralarga to'g'ri kelishini ta'minlash uchun hisoblanadi.

Haddan tashqari qisqarish nafaqat mopning tashqi ko'rinishiga, balki uning ishlashiga ham ta'sir qilishi mumkin, chunki u namlikni qanchalik samarali qabul qilishi va kirni tozalashga ta'sir qilishi mumkin. Doimiy qisqarish sinovi, hatto bir necha marta ishlatish va yuvishdan keyin ham mopning shakli va samaradorligini saqlab qolishga yordam beradi.

3. Mikrofiber mop sifatini nazorat qilish bo'yicha boshqa tanqidiy testlar

Qalinligi va qisqarishi mikrofiber mop sifatini nazorat qilishning eng muhim sinovlaridan ikkitasi bo'lsa-da, ishlab chiqaruvchilar mahsulotning umumiy ishlashini ta'minlash uchun baholashlari kerak bo'lgan boshqa muhim omillar mavjud.

-

Elyaf tarkibini aniqlash

Mikrofiber moplarda ishlatiladigan tolalarni aniqlash poliester va neylon kabi materiallar tarkibining talab qilinadigan texnik talablarga javob berishini ta'minlaydi. To'g'ri identifikatsiya qilish mop kerakli tozalash natijalarini, jumladan, changni ushlab turish, suvni singdirish va chidamlilikni ta'minlashga yordam beradi. -

Suvni singdirish testi

Mikrofiber moplar yuqori changni yutish qobiliyati bilan mashhur va bu xususiyatni sinab ko'rish mahsulotning haqiqiy tozalash sharoitida yaxshi ishlashini ta'minlash uchun zarurdir. Mopning to'yinganlik nuqtasiga yetguncha qancha suyuqlikni o'zlashtirishi mumkinligini o'lchash orqali ishlab chiqaruvchilar mopning tozalash samaradorligini o'lchashlari mumkin. -

Kuch va chidamlilik sinovi

Mikrofiber materialning mustahkamligini tekshirish, shuningdek, mopning takroriy foydalanishga bardosh bera olishini ta'minlash uchun ham muhimdir. Chidamlilik sinovi uzoq muddatli eskirishni taqlid qiladi va vaqt o'tishi bilan mop tolalari o'z tuzilishini va tozalash samaradorligini saqlab qoladimi yoki yo'qligini baholash uchun.

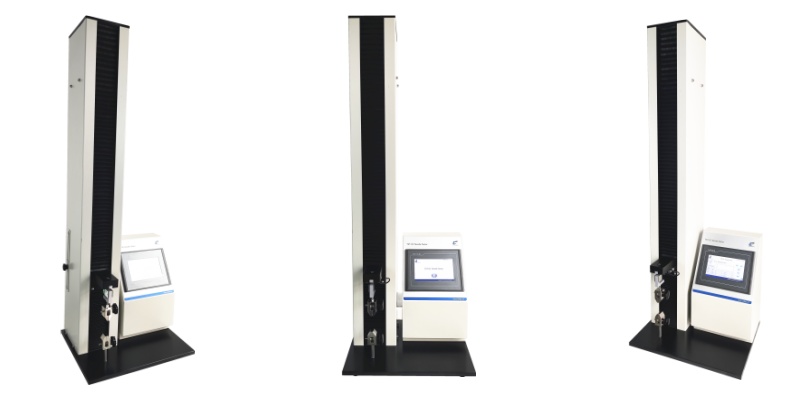

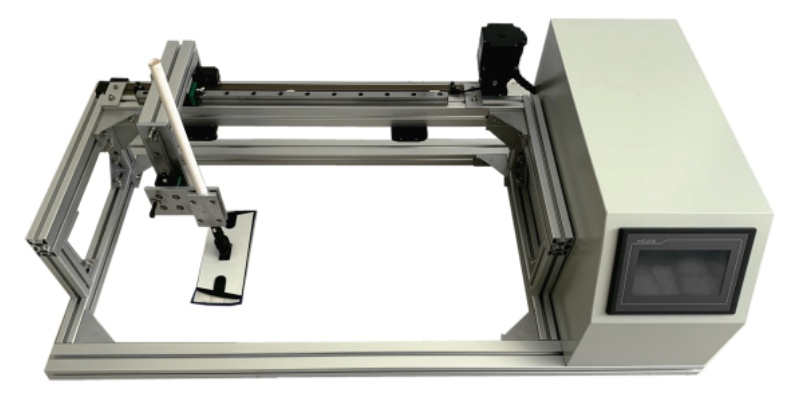

Mikrofiber mop sifatini nazorat qilish sinovi uchun tavsiya etilgan mahsulot

To'g'ri va ishonchli mikrofiber mop sifatini nazorat qilish sinovi uchun biz tavsiya qilamiz To'qimachilik qalinligi va qisqarishini tekshirgich Cell Instruments dan. Ushbu ilg'or sinov vositasi mikrofiber mopning qalinligi va qisqarishi uchun aniq o'lchovlarni ta'minlaydi, bu sizning mahsulotlaringiz eng yuqori standartlarga javob berishini ta'minlaydi.

To'qimachilik qalinligi va qisqarishini tekshirgich quyidagilar uchun mo'ljallangan:

Hujayra asboblari

Ishlab chiqaruvchi va zavod

Bizga qo'shiling va mop sifati uchun eng yaxshi laboratoriya sinov echimini oling

Paxta mop sifatini nazorat qilish sinovi haqida tez-tez so'raladigan savollar

Mikrofiber mop sifatini nazorat qilish sinovi mopning ishlash va sifat standartlariga javob berishini ta'minlash uchun qalinligi, qisqarishi, tolalar tarkibi va chidamliligi kabi omillarni baholash uchun bir qator baholashlarni o'z ichiga oladi.

Qalinligi sinovi mopning assimilyatsiya va chidamlilikning to'g'ri muvozanatiga ega bo'lishini ta'minlaydi. Juda yupqa mop changni yutish qobiliyatiga ega bo'lmasligi mumkin, juda qalin esa foydalanish qiyin bo'lishi va quritish uchun ko'proq vaqt talab qilishi mumkin.

Qalinligi, qisqarishi, changni yutish qobiliyati va tolalar tarkibi kabi asosiy xususiyatlarni muntazam sinovdan o'tkazish mikrofiber moplarning barqaror sifati va ishlashini ta'minlash uchun zarurdir.