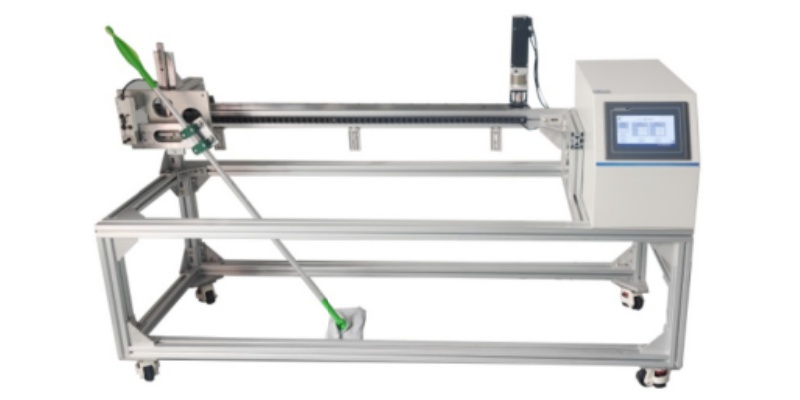

Chiziqni tekshirish mashinasi

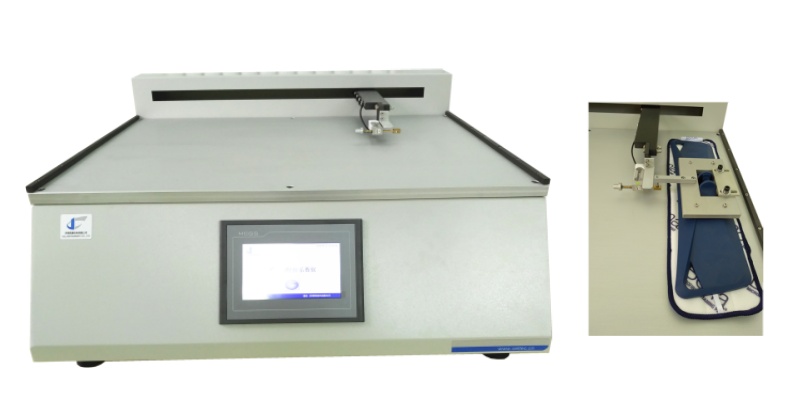

Mop sifatini tekshirish

- Uzilishga chidamlilik sinovi

Chiziqni sinovdan o'tkazish mashinasi - bu nosozlik yuzaga kelgunga qadar boshqariladigan kuchlanish (cho'zish) kuchini qo'llash orqali materiallarning mexanik xususiyatlarini baholash uchun ishlatiladigan muhim asbob. Ushbu mashina mop tutqichlari, tolalar va biriktiruvchi komponentlar kabi materiallarning mexanik stress ostida qanday ishlashi haqida aniq ma'lumotlarni taqdim etish uchun mo'ljallangan. kontekstida mop sifatini tekshirish, kuchlanishni tekshirish mashinasi ishlab chiqaruvchilarga asosiy mop komponentlarining mustahkamligi va chidamliligini baholashga yordam beradi.

Chiziqni tekshirish mashinasi qanday ishlaydi

Chiziqni sinovdan o'tkazish mashinasi namuna materialiga uning kuchlanish qarshiligini o'lchashda cho'zish kuchini qo'llash orqali ishlaydi. Mashinaning yuk xujayrasi ta'sir qilingan kuch miqdorini qayd qiladi, shu bilan birga namunaning cho'zilishi (cho'zilishi) nazorat qilinadi. Sinov material sindirilguncha, yirtilmaguncha yoki boshqa yo'l bilan ishlamaguncha davom ettiriladi.

In mop sifatini tekshirish, bu jarayon bir nechta asosiy jihatlarni baholash uchun ishlatiladi:

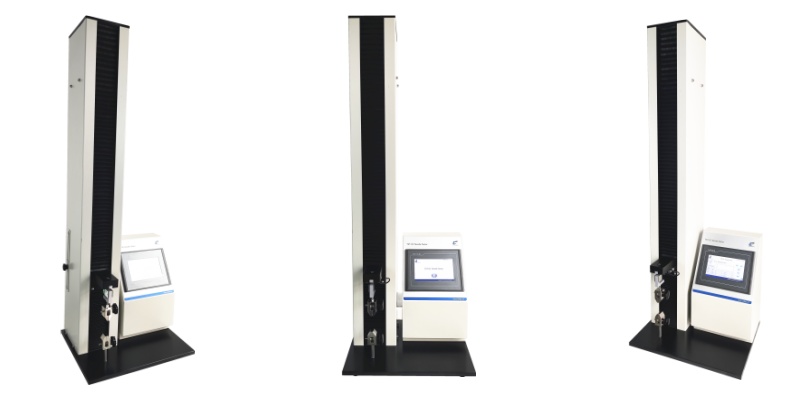

- Chidamlilik sinovi: Ushbu sinov materialning sinishidan oldin bardosh berishi mumkin bo'lgan maksimal kuchni o'lchaydi. Mop materiallari, masalan, mop boshida yoki tutqich materialida ishlatiladigan tolalar, foydalanish paytida qanchalik kuchlanishga bardosh bera olishini aniqlash uchun ushbu sinovdan o'tadi.

- Yirtilish kuchi sinovi: Ushbu test material yorilish boshlanganidan keyin yirtiqni yoyish uchun zarur bo'lgan kuchni aniqlaydi. Moplar uchun yirtiq kuchi tolalar va matolarning tortish yoki burish kabi kundalik stressda chidamliligini baholash uchun muhimdir.

- Buzilish kuchi sinovi: Bu kuchlanish kuchini sinashga o'xshaydi, lekin asosiy e'tibor materialning kuch ta'sirida to'liq parchalanish nuqtasiga qaratilgan bo'lib, ishlab chiqaruvchilarga material bardosh bera oladigan maksimal yukni tushunishga yordam beradi.

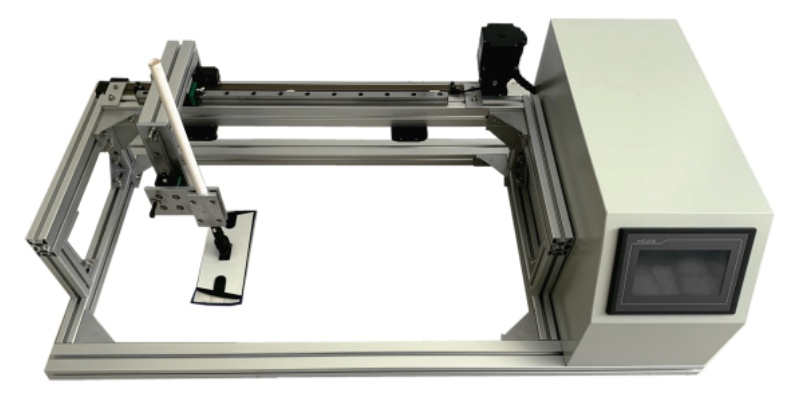

- 3 nuqtali egilish sinovi (Mop dastasi sinovi): Paspas tutqichlari, ham plastik, ham metall uchun, valentlik sinov mashinasi kundalik foydalanish paytida duch keladigan egilish kuchlarini taqlid qilishi mumkin. Uch nuqtali egilish sinovi tutqichning bosim ostida sinishi yoki egilishiga qarshi turish qobiliyatini o'lchaydi.

Chiziqni tekshirish mashinasining asosiy parametri

| Sinov oralig'i | 0-500N (yoki 50N, 100N, 200N va boshqalar) |

| Qon tomir | 800 mm (boshqa zarbalar uchun moslashtirilgan) |

| Sinov tezligi | 1~500mm/min |

| Siqilishning aniqligi | 0,01 mm |

| Aniqlik | 0.5% toʻliq oʻlchov |

| Namuna kengligi | 27 mm (ixtiyoriy kenglik mavjud) |

| Nazorat | PLC va HMI ekrani |

| Ma'lumotlarni chiqarish | Mikroprinter (ixtiyoriy), RS232 (ixtiyoriy) |

Mop sifatini tekshirish yechimi

Moplarning sifati va mustahkamligini ta'minlash ham tijorat, ham maishiy muhitda muhim ahamiyatga ega. A mop sifatini tekshirish uchun yechim valentlik sinov mashinasidan foydalangan holda, mop komponentlari kuchli, ishonchli va muddatidan oldin ishlamay turib, stressga bardosh bera oladi.

Ushbu yechim mop sinovining bir necha jihatlariga qaratilgan:

-

Mop komponentlarini yopishtirish kuchi: Chiziqni sinovdan o'tkazish mashinasi tolalar va tutqichlar kabi mopning turli qismlarining qanchalik yaxshi bog'langanligini baholaydi. Foydalanish vaqtida tolalar mop boshidan uzoqlashishini oldini olish uchun kuchli bog'lanish juda muhimdir.

-

Mop materiallarining mexanik mustahkamligi: Mashina mop komponentlarining umumiy mexanik xususiyatlarini, shu jumladan tolalar, tutqich va tutqich va mop boshi orasidagi ulagichni baholaydi. Bu mopning chidamliligi va uzoq umrini baholash uchun muhimdir.

Chiziqni tekshirish mashinasining asosiy xususiyatlari

The Chiziqni tekshirish mashinasi mop ishlab chiqaruvchilar uchun bir qancha afzalliklarni taqdim etadi

Aniqlik va aniqlik

Mashina valentlik kuchi, cho'zilish, yirtilish kuchi va sinish kuchining yuqori aniqlikdagi o'qishlarini taklif qiladi, bu esa uni sifat nazorati va tadqiqot uchun mos qiladi.

Foydalanuvchi uchun qulay interfeys

Intuitiv interfeysga ega bo'lgan kuchlanishni sinovdan o'tkazish mashinasi, hatto materiallarni sinashda minimal tajribaga ega bo'lgan xodimlar uchun ham oson ishlaydi.

Sinovlarning keng doirasi

Mashina mop komponentlari uchun keng ko'lamli sinovlarni qo'llab-quvvatlaydi, mop tolalarining kuchlanish kuchini sinashdan tortib, mop tutqichlarining moslashuvchanligini baholashgacha.

Ilg'or yuk xujayrasi texnologiyasi

Yuk xujayrasi qo'llaniladigan kuchni o'lchash va uni to'g'ri qayd etish orqali izchil va ishonchli ma'lumotlarni taqdim etadi, bu esa sinov natijalarini takrorlanishini ta'minlaydi.

Sinov jarayoni va ahamiyati

Mop materiallarida valentlik sinovlarini o'tkazish jarayoni quyidagi bosqichlarni o'z ichiga oladi:

-

Namuna tayyorlash: Mopning tarkibiy qismlarining namunalari (tutqich, tola yoki biriktiruvchi material) belgilangan o'lchamlarga muvofiq tayyorlanadi.

-

Sinovni sozlash: Namuna qisish sinov mashinasiga xavfsiz tarzda joylashtirilgan. Mop tutqichlari, ham plastik, ham metall uchun, mashina ma'lum bir tezlikda kuch qo'llaydi va foydalanish paytida tutqich duch keladigan kuchlarni taqlid qiladi.

-

Testning bajarilishi: Mashina material deformatsiyalanmaguncha, yirtilmaguncha yoki parchalanmaguncha doimiy ravishda kuchayib boradi. Ushbu jarayon davomida kuch va cho'zilish o'lchanadi va qayd etiladi.

-

Ma'lumotlarni tahlil qilish: Sinovdan so'ng ma'lumotlar materialning mustahkamligi, elastikligi va sinishi yoki yirtilishiga qarshiligini aniqlash uchun tahlil qilinadi. Ushbu natijalar mop komponentlari mo'ljallangan xizmat muddati davomida samarali ishlashini ta'minlash uchun juda muhimdir.

The Mop uchun tortishish sinov mashinasi yuqori sifatli, bardoshli mop mahsulotlarini ishlab chiqarishni maqsad qilgan ishlab chiqaruvchilar uchun muhim vositadir. Uzilish kuchi, yirtilib ketish kuchi, sinish kuchi va tutqichning moslashuvchanligi uchun keng qamrovli sinovlarni ta'minlash orqali mashina mop komponentlarining qat'iy sifat standartlariga javob berishini ta'minlaydi. A mop sifatini tekshirish uchun yechim bu nafaqat mahsulotni ishlab chiqishni yaxshilaydi, balki iste'molchilarga ishonchli, uzoq muddatli tozalash vositalarini olishini kafolatlaydi.

Issiqlik qisqarishi sinovi haqida tez-tez so'raladigan savollar

1. Mop sifatini sinashda valentlik mustahkamligini tekshirishdan maqsad nima?

Siqilish kuchini sinash materialning, masalan, mop tolasi yoki tutqichining sinishdan oldin qancha kuchga bardosh bera olishini o'lchaydi. Bu mop komponentlarining kundalik foydalanish uchun etarlicha bardoshli bo'lishini ta'minlaydi.

2. Mop tutqichlarini sinash uchun valentlikni tekshirish mashinasi qanday ishlaydi?

Mashina mop tutqichiga egilib yoki sinmaguncha boshqariladigan kuchni qo'llaydi. Ushbu test tutqichning mustahkamligini va sinishga chidamliligini aniqlash uchun haqiqiy stressni simulyatsiya qiladi.

3. Nima uchun mopni tekshirishda yirtiq kuchi muhim?

Yirtilish kuchini sinovdan o'tkazadi, mop tolalari stress ostida yirtilishga qanchalik yaxshi qarshilik ko'rsatadi va foydalanish paytida tolalar parchalanmasdan samarali ishlashini ta'minlaydi.

4. Mop sifatini ta'minlash uchun valentlikni tekshirish mashinasidan foydalanishning afzalliklari nimada?

Chiziqni sinovdan o'tkazish mashinasidan foydalanish ishlab chiqaruvchilarga mahsulotning chidamliligini yaxshilashga, nuqsonlarni kamaytirishga, standartlarga muvofiqligini ta'minlashga va yuqori sifatli mahsulotlarni etkazib berish orqali mijozlar ehtiyojini qondirishga yordam beradi.

Tegishli mop sifatini nazorat qilish yechimi

Ishonchli kuchlanish sinov mashinasini qidiryapsizmi?

Sifatni nazorat qilish jarayonlarini eng zamonaviy uskunalar bilan optimallashtirish imkoniyatini qo‘ldan boy bermang.