Mop Friction Force Testing

Mop Quality Control Analysis

Mop Friction Testing

Mop friction force testing is a critical procedure for evaluating the performance and quality of mops, especially for manufacturers who aim to improve their products. This testing method helps in understanding how different mop materials and designs affect friction, which directly influences the cleaning efficiency, durability, and user comfort. In this article, we will explore the importance of mop friction force testing, how it works, and how it supports quality control analysis to ensure better mop performance.

What is Mop Friction Force Testing?

Mop friction force testing is a method used to measure the resistance encountered by a mop during its movement across a surface. This resistance, referred to as friction, plays a significant role in the overall cleaning performance of the mop.

Importance of Mop Friction Testing

Mop friction force testing helps manufacturers find the ideal balance of friction, ensuring that their products are both easy to use and highly effective in cleaning.

Mop friction force testing helps manufacturers find the ideal balance of friction, ensuring that their products are both easy to use and highly effective in cleaning.

The Mop Friction Force Testing Process

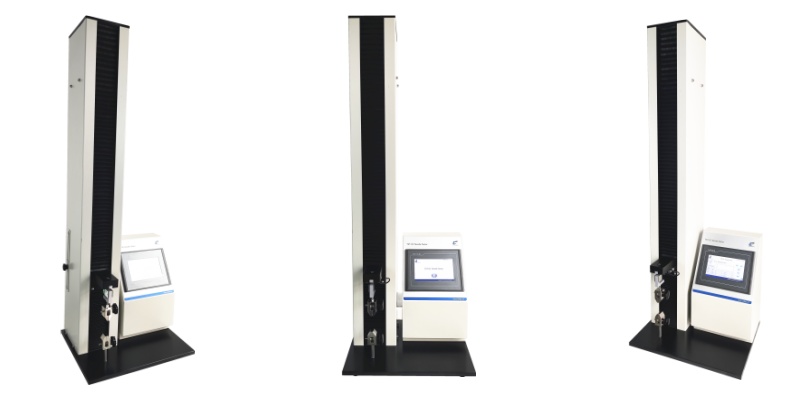

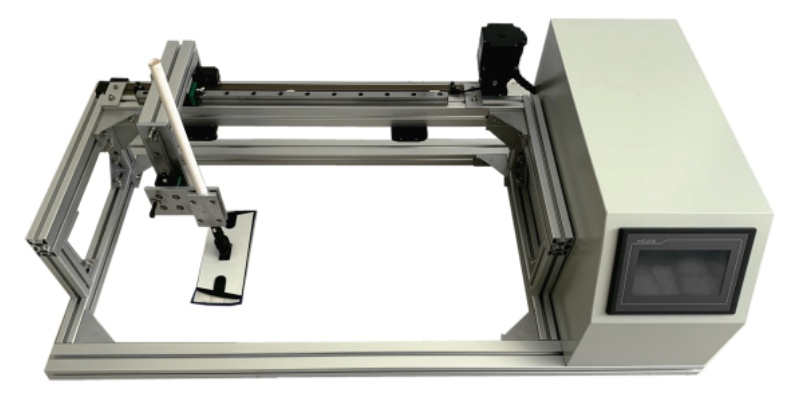

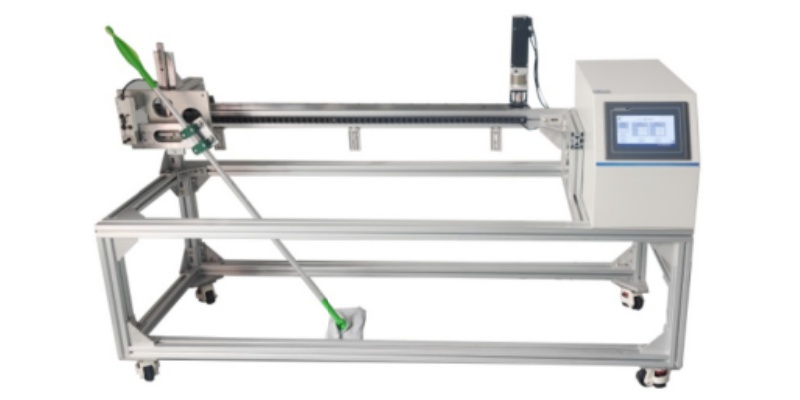

The mop friction force testing method typically involves a test apparatus such as the MopFric-01 Mop Friction Tester, which is designed to measure the frictional forces that occur as the mop moves across different surfaces. During the test, the mop is subjected to controlled conditions, with specific parameters for load and speed, simulating typical cleaning scenarios.

How the MopFric-01 Mop Friction Tester Works

The MopFric-01 Mop Friction Tester measures the force required to move the mop back and forth, simulating the motion during cleaning. It employs a high-precision loadcell to capture and record friction force data in real time. This data is invaluable for manufacturers looking to fine-tune the design of their mops. By adjusting factors such as the mop’s material, the texture of its fibers, or the mop head’s weight, manufacturers can optimize the product for better user experience and cleaning performance.

The tester measures friction during reciprocating motion, providing two-way frictional force data in one complete test cycle.

Mop Quality Control Analysis Through Friction Testing

Mop friction force testing plays a crucial role in mop quality control analysis. By consistently measuring friction forces, manufacturers can ensure that their products meet quality standards and offer a balance between effective cleaning and user comfort. Here’s how it contributes to the quality control process:

- Consistency in Performance: Repeated friction force tests ensure that each mop design maintains consistent cleaning performance, which is essential for brand reputation and customer satisfaction.

- Material Optimization: Different mop materials, such as microfiber, cotton, or synthetic fibers, may exhibit varying levels of friction. Testing allows manufacturers to select the optimal materials that provide the best balance between friction and durability.

- Design Adjustments: Friction testing can reveal how different mop head designs affect cleaning performance. Manufacturers can use this data to make design modifications, improving both the efficiency and comfort of the mop.

- Durability Assessment: The tester can also simulate extended use, providing insight into how friction changes over time. This helps in evaluating the longevity of the mop and predicting how it will perform after repeated use.

Benefits of Mop Friction Force Testing

Improved Cleaning Efficiency

Testing allows manufacturers to create mops with the ideal friction level for effective cleaning without causing undue fatigue. By analyzing how friction influences cleaning performance, manufacturers can ensure that their mops pick up dirt and debris efficiently.

Enhanced User Experience

Mop friction force testing helps manufacturers optimize the design of mops to minimize user fatigue. By fine-tuning the balance of friction, mops can become easier to push or pull, improving comfort during cleaning sessions.

Better Product Design

With friction force testing, manufacturers can experiment with various materials and mop head designs to achieve the optimal balance between ease of use and cleaning performance. This is crucial for creating high-quality, user-friendly products.

Quality Assurance

By using mop friction force testing in mop quality control analysis, manufacturers can ensure that every mop meets the necessary standards for performance and reliability. This also helps in maintaining product consistency across batches.

Mop friction force testing is an essential procedure for evaluating the performance, durability, and overall quality of mops. By using tools like the MopFric-01 Mop Friction Tester, manufacturers can gain valuable data that helps them optimize their mop designs for better cleaning efficiency and user comfort.

FAQs About Mop COF Testing

1. What is the Mop Friction Testing Machine used for mop quality control analysis?

The Mop Friction Testing Instrument measures the frictional forces experienced by a mop during use, helping manufacturers optimize mop design for better cleaning efficiency and user comfort.

2. How does mop friction testing affect cleaning performance?

Higher friction can improve cleaning effectiveness by enhancing the mop’s contact with the surface, while too much friction may lead to user fatigue. Low friction can reduce cleaning efficiency.

3. Why is mop friction testing important for mop quality control analysis?

Mop friction testing ensures that each product meets the desired performance standards, allowing manufacturers to maintain consistency, optimize materials and designs, and improve durability.

4. What materials are typically tested for friction in mops?

Materials such as microfiber, cotton, and synthetic fibers are commonly tested for their frictional properties, as each material exhibits different levels of resistance during use.